Page 259 - Automotive Engineering Powertrain Chassis System and Vehicle Body

P. 259

Steering CHAPTER 9.1

right on right-hand drive) and tie rod joints

screwed into the sides of the steering rack (side

take-off).

Type 2 Pinion gear in vehicle centre and tie rods

taken off at the sides.

Type 3 Pinion gear to the side and centre take-off,

i.e. the tie rods are fixed in the vehicle centre to the

steering rack.

Type 4 ‘Short steering’ with off-centre pinion gear

and both tie rods fixed to one side of the steering rack

(Fig. 9.1-1).

Types 1 and 3 are the solutions generally used,

whereas Type 2 was found in some Porsche vehicles,

and Type 4 used to be preferred by Audi and VW.

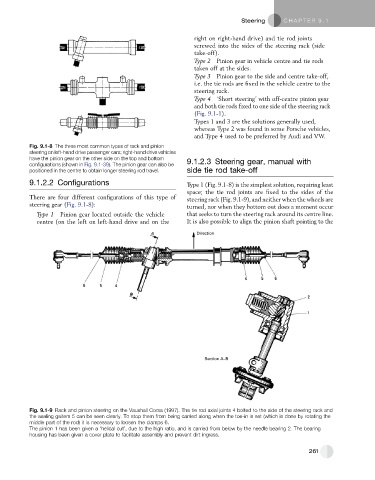

Fig. 9.1-8 The three most common types of rack and pinion

steering on left-hand drive passenger cars; right-hand drive vehicles

have the pinion gear on the other side on the top and bottom 9.1.2.3 Steering gear, manual with

configurations (shown in Fig. 9.1-39). The pinion gear can also be

positioned in the centre to obtain longer steering rod travel. side tie rod take-off

9.1.2.2 Configurations Type 1 (Fig. 9.1-8) is the simplest solution, requiring least

space; the tie rod joints are fixed to the sides of the

There are four different configurations of this type of steering rack (Fig. 9.1-9), and neither when the wheels are

steering gear (Fig. 9.1-8): turned, nor when they bottom out does a moment occur

Type 1 Pinion gear located outside the vehicle that seeks to turn the steering rack around its centre line.

centre (on the left on left-hand drive and on the It is also possible to align the pinion shaft pointing to the

Fig. 9.1-9 Rack and pinion steering on the Vauxhall Corsa (1997). The tie rod axial joints 4 bolted to the side of the steering rack and

the sealing gaiters 5 can be seen clearly. To stop them from being carried along when the toe-in is set (which is done by rotating the

middle part of the rod) it is necessary to loosen the clamps 6.

The pinion 1 has been given a ‘helical cut’, due to the high ratio, and is carried from below by the needle bearing 2. The bearing

housing has been given a cover plate to facilitate assembly and prevent dirt ingress.

261