Page 298 - Automotive Engineering Powertrain Chassis System and Vehicle Body

P. 298

Tyres and wheels C HAPTER 10.1

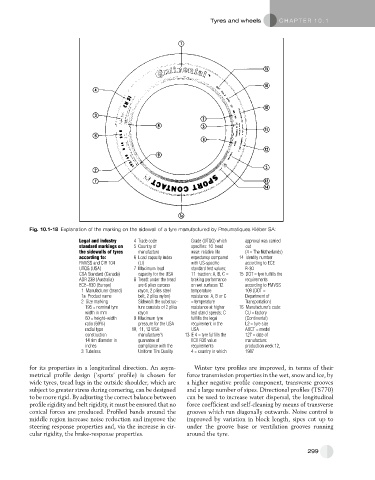

Fig. 10.1-18 Explanation of the marking on the sidewall of a tyre manufactured by Pneumatiques Kle ´ ber SA:

Legal and industry 4 Trade code Grade (UTQG) which approval was carried

standard markings on 5 Country of specifies: 10 tread out

the sidewalls of tyres manufacture wear: relative life (4 = The Netherlands)

according to: 6 Load capacity index expectancy compared 14 identity number

FMVSS and CIR 104 (LI) with US-specific according to ECE

UTQG (USA) 7 Maximum load standard test values; R-30

CSA Standard (Canada) capacity for the USA 11 traction: A, B, C = 15 DOT = tyre fulfills the

ADR 23B (Australia) 8 Tread: under the tread braking performance requirements

ECE–R30 (Europe) are 6 plies carcass on wet surfaces 12 according to FMVSS

1 Manufacturer (brand) rayon, 2 plies steel temperature 109 (DOT =

1a Product name belt, 2 plies nylon) resistance: A, B or C Department of

2 Size marking Sidewall: the substruc- = temperature Transportation)

195 = nominal tyre ture consists of 2 plies resistance at higher 16 Manufacturer’s code:

width in mm rayon test stand speeds; C CU = factory

60 = height–width 9 Maximum tyre fulfills the legal (Continental)

ratio (60%) pressure for the USA requirement in the L2 = tyre size

radial type 10, 11, 12 USA: USA AXCT = model

construction manufacturer’s 13 E 4 = tyre fulfills the 127 = date of

14 rim diameter in guarantee of ECE R30 value manufacture:

inches compliance with the requirements production week 12,

3 Tubeless Uniform Tire Quality 4 = country in which 1987

for its properties in a longitudinal direction. An asym- Winter tyre profiles are improved, in terms of their

metrical profile design (‘sports’ profile) is chosen for force transmission properties in the wet, snow and ice, by

wide tyres, tread lugs in the outside shoulder, which are a higher negative profile component, transverse grooves

subject to greater stress during cornering, can be designed and a large number of sipes. Directional profiles (TS770)

to be more rigid. By adjusting the correct balance between can be used to increase water dispersal, the longitudinal

profile rigidity and belt rigidity, it must be ensured that no force coefficient and self-cleaning by means of transverse

conical forces are produced. Profiled bands around the grooves which run diagonally outwards. Noise control is

middle region increase noise reduction and improve the improved by variation in block length, sipes cut up to

steering response properties and, via the increase in cir- under the groove base or ventilation grooves running

cular rigidity, the brake-response properties. around the tyre.

299