Page 302 - Automotive Engineering Powertrain Chassis System and Vehicle Body

P. 302

Tyres and wheels C HAPTER 10.1

Regardless of the material, the wheels must be

stamped with a marking containing the most important

data (Fig. 10.1-25).

10.1.3.4 Wheel mountings

Many strength requirements are placed on the wheel disc

sitting in the rim (or the wheel spider on alloy wheels); it

has to absorb vertical, lateral and longitudinal forces

coming from the road and transfer them to the wheel

hub via the fixing bolts.

The important thing here is that the contact area of

the attachment faces, known as the ‘mirror’, should sit

evenly and, for passenger cars, that the hub flange should

have a slightly larger diameter (Fig. 10.1-23), otherwise

it is possible that the outer edge of the hub will dig into

the contact area, with a loss of torque on the bolts. The

notch effect can also cause a fatigue fracture leading to an

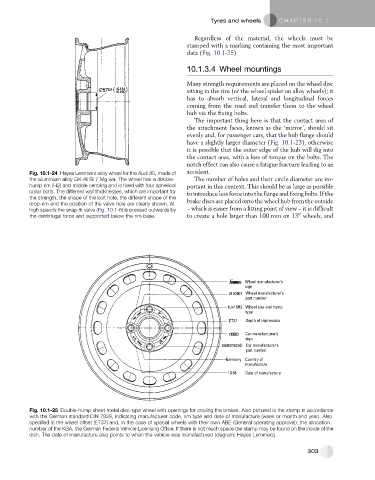

Fig. 10.1-24 Hayes Lemmerz alloy wheel for the Audi 80, made of accident.

the aluminium alloy GK-Al Si 7 Mg wa. The wheel has a double- The number of holes and their circle diameter are im-

hump rim (H2) and middle centring and is fixed with four spherical portant in this context. This should be as large as possible

collar bolts. The different wall thicknesses, which are important for tointroduceless force intotheflangeandfixing bolts.Ifthe

the strength, the shape of the bolt hole, the different shape of the brake discs are placed onto the wheel hub from the outside

drop-rim and the position of the valve hole are clearly shown. At

high speeds the snap-fit valve (Fig. 10.1-6) is pressed outwards by – which is easier from a fitting point of view – it is difficult

00

the centrifugal force and supported below the rim base. to create a hole larger than 100 mm on 13 wheels, and

Wheel manufacturer’s

sign

2150907 Wheel manufacturer’s

part number

6Jx15H2 Wheel size and hump

type

ET37 Depth of impression

Car manufacturer’s

sign

8A0601025G Car manufacturer’s

part number

Germany Country of

manufacture

10.98 Date of manufacture

Fig. 10.1-25 Double-hump sheet metal disc-type wheel with openings for cooling the brakes. Also pictured is the stamp in accordance

with the German standard DIN 7829, indicating manufacturer code, rim type and date of manufacture (week or month and year). Also

specified is the wheel offset (ET37) and, in the case of special wheels with their own ABE (General operating approval), the allocation

number of the KBA, the German Federal Vehicle Licensing Office. If there is not much space the stamp may be found on the inside of the

dish. The date of manufacture also points to when the vehicle was manufactured (diagram: Hayes Lemmerz).

303