Page 520 - Automotive Engineering Powertrain Chassis System and Vehicle Body

P. 520

Terminology and overview of vehicle structure types C HAPTER 16.1

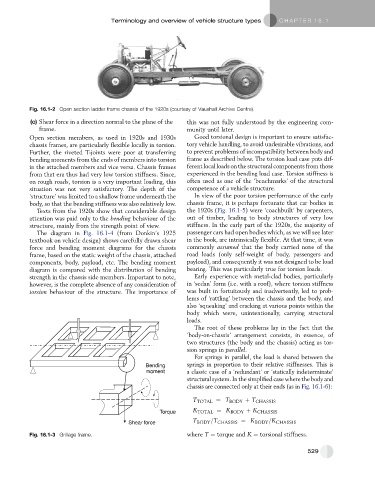

Fig. 16.1-2 Open section ladder frame chassis of the 1920s (courtesy of Vauxhall Archive Centre).

(c) Shear force in a direction normal to the plane of the this was not fully understood by the engineering com-

frame. munity until later.

Open section members, as used in 1920s and 1930s Good torsional design is important to ensure satisfac-

chassis frames, are particularly flexible locally in torsion. tory vehicle handling, to avoid undesirable vibrations, and

Further, the riveted T-joints were poor at transferring to prevent problems of incompatibility between body and

bending moments from the ends of members into torsion frame as described below. The torsion load case puts dif-

in the attached members and vice versa. Chassis frames ferent local loads on the structural components from those

from that era thus had very low torsion stiffness. Since, experienced in the bending load case. Torsion stiffness is

on rough roads, torsion is a very important loading, this often used as one of the ‘benchmarks’ of the structural

situation was not very satisfactory. The depth of the competence of a vehicle structure.

‘structure’ was limited to a shallow frame underneath the In view of the poor torsion performance of the early

body, so that the bending stiffness was also relatively low. chassis frame, it is perhaps fortunate that car bodies in

Texts from the 1920s show that considerable design the 1920s (Fig. 16.1-5) were ‘coachbuilt’ by carpenters,

attention was paid only to the bending behaviour of the out of timber, leading to body structures of very low

structure, mainly from the strength point of view. stiffness. In the early part of the 1920s, the majority of

The diagram in Fig. 16.1-4 (from Donkin’s 1925 passenger cars had open bodies which, as we will see later

textbook on vehicle design) shows carefully drawn shear in the book, are intrinsically flexible. At that time, it was

force and bending moment diagrams for the chassis commonly assumed that the body carried none of the

frame, based on the static weight of the chassis, attached road loads (only self-weight of body, passengers and

components, body, payload, etc. The bending moment payload), and consequently it was not designed to be load

diagram is compared with the distribution of bending bearing. This was particularly true for torsion loads.

strength in the chassis side members. Important to note, Early experience with metal-clad bodies, particularly

however, is the complete absence of any consideration of in ‘sedan’ form (i.e. with a roof), where torsion stiffness

torsion behaviour of the structure. The importance of was built in fortuitously and inadvertently, led to prob-

lems of ‘rattling’ between the chassis and the body, and

also ‘squeaking’ and cracking at various points within the

body which were, unintentionally, carrying structural

loads.

The root of these problems lay in the fact that the

‘body-on-chassis’ arrangement consists, in essence, of

two structures (the body and the chassis) acting as tor-

sion springs in parallel.

For springs in parallel, the load is shared between the

Bending springs in proportion to their relative stiffnesses. This is

moment a classic case of a ‘redundant’ or ‘statically indeterminate’

structural system. In the simplified case where the body and

chassis are connected only at their ends (as in Fig. 16.1-6):

T TOTAL ¼ T BODY þ T CHASSIS

Torque K TOTAL ¼ K BODY þ K CHASSIS

T BODY =T ¼ K BODY =K

Shear force CHASSIS CHASSIS

Fig. 16.1-3 Grillage frame. where T ¼ torque and K ¼ torsional stiffness.

529