Page 521 - Automotive Engineering Powertrain Chassis System and Vehicle Body

P. 521

CHAP TER 1 6. 1 Terminology and overview of vehicle structure types

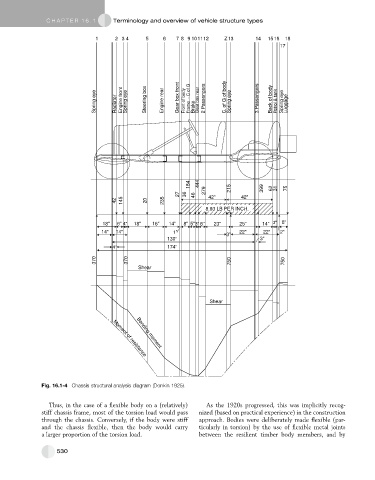

1 2 3 4 5 6 7 8 9 10 11 12 Z 13 14 15 16 18

17

Spring eye Radiator Engine front Spring eye Steering box Engine rear Gear box front Front of body Frame - C of G Brake Gear box rear 2 Passengers C. of G of body Spring eye 3 Passengers Back of body Petrol & tank Spring eye Luggage

184 444 215 399 62 31 75

27 36 46 279

42 145 20 235 42" 42"

8.93 LB PER INCH.

18" 6" 4" 18" 16" 14" 8" 5" 3" 6" 23" 25" 14" 3" 8"

14" 14" 1" 22" 22" 2"

3"

130" 3"

4" 174"

370 370 750 750

Shear

Shear

Bending moment

Moment of resistance

Fig. 16.1-4 Chassis structural analysis diagram (Donkin 1925).

Thus, in the case of a flexible body on a (relatively) As the 1920s progressed, this was implicitly recog-

stiff chassis frame, most of the torsion load would pass nized (based on practical experience) in the construction

through the chassis. Conversely, if the body were stiff approach. Bodies were deliberately made flexible (par-

and the chassis flexible, then the body would carry ticularly in torsion) by the use of flexible metal joints

a larger proportion of the torsion load. between the resilient timber body members, and by

530