Page 522 - Automotive Engineering Powertrain Chassis System and Vehicle Body

P. 522

Terminology and overview of vehicle structure types C HAPTER 16.1

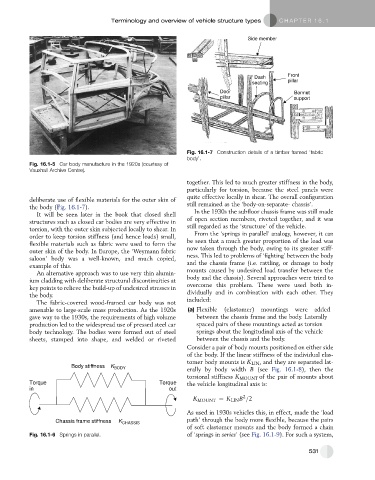

Side member

Front

Dash

seating pillar

Door Bonnet

pillar support

Fig. 16.1-7 Construction details of a timber framed ‘fabric

body’.

Fig. 16.1-5 Car body manufacture in the 1920s (courtesy of

Vauxhall Archive Centre).

together. This led to much greater stiffness in the body,

particularly for torsion, because the steel panels were

quite effective locally in shear. The overall configuration

deliberate use of flexible materials for the outer skin of

the body (Fig. 16.1-7). still remained as the ‘body-on-separate- chassis’.

It will be seen later in the book that closed shell In the 1930s the subfloor chassis frame was still made

structures such as closed car bodies are very effective in of open section members, riveted together, and it was

torsion, with the outer skin subjected locally to shear. In still regarded as the ‘structure’ of the vehicle.

order to keep torsion stiffness (and hence loads) small, From the ‘springs in parallel’ analogy, however, it can

flexible materials such as fabric were used to form the be seen that a much greater proportion of the load was

outer skin of the body. In Europe, the ‘Weymann fabric now taken through the body, owing to its greater stiff-

saloon’ body was a well-known, and much copied, ness. This led to problems of ‘fighting’ between the body

example of this. and the chassis frame (i.e. rattling, or damage to body

An alternative approach was to use very thin alumin- mounts caused by undesired load transfer between the

ium cladding with deliberate structural discontinuities at body and the chassis). Several approaches were tried to

key points to relieve the build-up of undesired stresses in overcome this problem. These were used both in-

dividually and in combination with each other. They

the body.

included:

The fabric-covered wood-framed car body was not

amenable to large-scale mass production. As the 1920s (a) Flexible (elastomer) mountings were added

gave way to the 1930s, the requirements of high volume between the chassis frame and the body. Laterally

production led to the widespread use of pressed steel car spaced pairs of these mountings acted as torsion

body technology. The bodies were formed out of steel springs about the longitudinal axis of the vehicle

sheets, stamped into shape, and welded or riveted between the chassis and the body.

Consider a pair of body mounts positioned on either side

of the body. If the linear stiffness of the individual elas-

tomer body mounts is K LIN , and they are separated lat-

Body stiffness K BODY erally by body width B (see Fig. 16.1-8), then the

torsional stiffness K MOUNT of the pair of mounts about

Torque Torque the vehicle longitudinal axis is:

in out

2

K MOUNT ¼ K LIN B =2

As used in 1930s vehicles this, in effect, made the ‘load

Chassis frame stiffness K CHASSIS path’ through the body more flexible, because the pairs

of soft elastomer mounts and the body formed a chain

Fig. 16.1-6 Springs in parallel. of ‘springs in series’ (see Fig. 16.1-9). For such a system,

531