Page 524 - Automotive Engineering Powertrain Chassis System and Vehicle Body

P. 524

Terminology and overview of vehicle structure types C HAPTER 16.1

A 24" B 24" C 57" D 56"

E

6283 LBS. 8378 LBS.

FT./DEG. FT./DEG. 6283 LBS. FT./DEG. 2960 LBS. FT./DEG.

29800 LBS. FT./DEG./FT. RUN 13830 LBS. FT./DEG./FT. RUN

2566 LBS. 17450 LBS.

FT/DEG./FT. RUN FT/DEG./FT. RUN

DEFLECTION DIAGRAM 13/64"

39/64" 31/64" 25/64" DEFL. @ 75" RADIUS : 1/4° TWIST(APP .)

TOTAL DEFLECTION @ 75" RADIUS 1" : 5/16" DEFL.

= 39/64" −1290 LBS. FT./DEGREE

= 13550 LBS. FT./DEGREE/FT.RUN

Fig. 16.1-10 Cruciform-braced chassis frame (Booth 1938 by permission Council of I.Mech.E.).

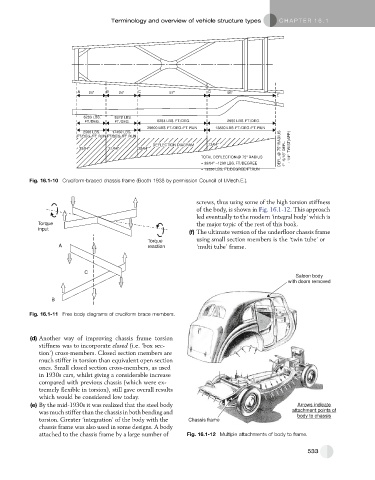

screws, thus using some of the high torsion stiffness

of the body, is shown in Fig. 16.1-12. This approach

led eventually to the modern ‘integral body’ which is

Torque the major topic of the rest of this book.

input

(f) The ultimate version of the underfloor chassis frame

Torque using small section members is the ‘twin tube’ or

A reaction ‘multi tube’ frame.

C

Saloon body

with doors removed

B

Fig. 16.1-11 Free body diagrams of cruciform brace members.

(d) Another way of improving chassis frame torsion

stiffness was to incorporate closed (i.e. ‘box sec-

tion’) cross-members. Closed section members are

much stiffer in torsion than equivalent open section

ones. Small closed section cross-members, as used

in 1930s cars, whilst giving a considerable increase

compared with previous chassis (which were ex-

tremely flexible in torsion), still gave overall results

which would be considered low today.

(e) By the mid-1930s it was realized that the steel body Arrows indicate

was much stiffer than the chassis in both bending and attachment points of

body to chassis

torsion. Greater ‘integration’ of the body with the Chassis frame

chassis frame was also used in some designs. A body

attached to the chassis frame by a large number of Fig. 16.1-12 Multiple attachments of body to frame.

533