Page 526 - Automotive Engineering Powertrain Chassis System and Vehicle Body

P. 526

Terminology and overview of vehicle structure types C HAPTER 16.1

Fig. 16.1-14 Sheet steel backbone chassis (courtesy Lotus Cars Ltd).

16.1.2.2.2 Triangulated tube structure structure if the triangulated bays (including edges) are

treated as structural surfaces.

The triangulated tube arrangement is not limited to This method of construction is best suited to low

backbone structures. Perhaps a more common approach volume production because of low tooling costs. It is not

using this principle, particularly for sports cars, is the well suited to mass production due to complication and

‘bathtub’ layout, in which the triangulated structure labour-intensive manufacture.

surrounds the outside of the body. A classic example is

the Caterham shown in Fig. 16.1-16. This approach has

the advantage that the coachwork can consist of thin 16.1.2.2.3 Incorporation of roll cage

sheet metal cladding, attached directly to the frame- into structure

work. If the vehicle is an open car, the large cockpit in- The ultimate way of using the ‘tube’ principle is to make

terrupts the ‘closed box’ needed for torsion stiffness. In the tube encompass the whole car body. A version of this

such a case, torsion stiffness is sometimes restored by is shown in the triangulated sports car structure shown in

‘boxing in’ either the transmission tunnel, or the dash/ Fig. 16.1-17. The triangulated ‘roll cage’ now extends

cowl area (or both) with triangulated bays. Stiffening of around the passenger compartment. The enclosed cross-

the edges of the passenger compartment top opening, sectional area of the body is thus very large, and hence

particularly at the corners, can also bring some im- the torsion constant is large also.

provement to the torsional performance. The principles Roots and co-workers studied the torsion stiffness of

of the simple structural surfaces method (see later in a racing vehicle in which the roll cage was incorporated

Chapter 16.2) can still be applied to this type of into the structure in a range of different ways. They

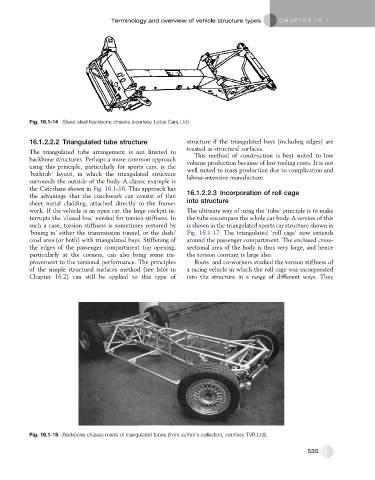

Fig. 16.1-15 Backbone chassis made of triangulated tubes (from author’s collection, courtesy TVR Ltd).

535