Page 531 - Automotive Engineering Powertrain Chassis System and Vehicle Body

P. 531

CHAP TER 1 6. 1 Terminology and overview of vehicle structure types

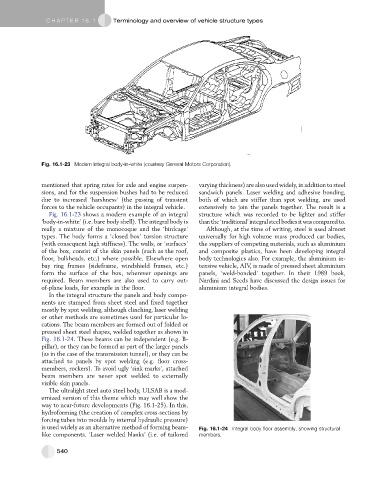

Fig. 16.1-23 Modern integral body-in-white (courtesy General Motors Corporation).

mentioned that spring rates for axle and engine suspen- varying thickness) are also used widely, in addition to steel

sions, and for the suspension bushes had to be reduced sandwich panels. Laser welding and adhesive bonding,

due to increased ‘harshness’ (the passing of transient both of which are stiffer than spot welding, are used

forces to the vehicle occupants) in the integral vehicle. extensively to join the panels together. The result is a

Fig. 16.1-23 shows a modern example of an integral structure which was recorded to be lighter and stiffer

‘body-in-white’ (i.e. bare body shell). The integral body is thanthe‘traditional’integralsteelbodiesitwascomparedto.

really a mixture of the monocoque and the ‘birdcage’ Although, at the time of writing, steel is used almost

types. The body forms a ‘closed box’ torsion structure universally for high volume mass produced car bodies,

(with consequent high stiffness). The walls, or ‘surfaces’ the suppliers of competing materials, such as aluminium

of the box, consist of the skin panels (such as the roof, and composite plastics, have been developing integral

floor, bulkheads, etc.) where possible. Elsewhere open body technologies also. For example, the aluminium in-

bay ring frames (sideframe, windshield frames, etc.) tensive vehicle, AIV, is made of pressed sheet aluminium

form the surface of the box, wherever openings are panels, ‘weld-bonded’ together. In their 1989 book,

required. Beam members are also used to carry out- Nardini and Seeds have discussed the design issues for

of-plane loads, for example in the floor. aluminium integral bodies.

In the integral structure the panels and body compo-

nents are stamped from sheet steel and fixed together

mostly by spot welding, although clinching, laser welding

or other methods are sometimes used for particular lo-

cations. The beam members are formed out of folded or

pressed sheet steel shapes, welded together as shown in

Fig. 16.1-24. These beams can be independent (e.g. B-

pillar), or they can be formed as part of the larger panels

(as in the case of the transmission tunnel), or they can be

attached to panels by spot welding (e.g. floor cross-

members, rockers). To avoid ugly ‘sink marks’, attached

beam members are never spot welded to externally

visible skin panels.

The ultralight steel auto steel body, ULSAB is a mod-

ernized version of this theme which may well show the

way to near-future developments (Fig. 16.1-25). In this,

hydroforming (the creation of complex cross-sections by

forcing tubes into moulds by internal hydraulic pressure)

is used widely as an alternative method of forming beam- Fig. 16.1-24 Integral body floor assembly, showing structural

like components. ‘Laser welded blanks’ (i.e. of tailored members.

540