Page 523 - Automotive Engineering Powertrain Chassis System and Vehicle Body

P. 523

CHAP TER 1 6. 1 Terminology and overview of vehicle structure types

A common solution was the use of cruciform bracing.For

this, a cross-shaped brace, made usually of open channel

section members, was incorporated into the chassis

frame as shown in Fig. 16.1-10. It was necessary for the

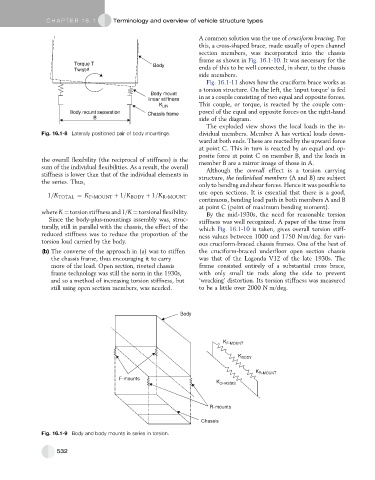

Torque T Body

Twist θ ends of this to be well connected, in shear, to the chassis

side members.

Fig. 16.1-11 shows how the cruciform brace works as

a torsion structure. On the left, the ‘input torque’ is fed

Body mount

linear stiffness in as a couple consisting of two equal and opposite forces.

K LIN This couple, or torque, is reacted by the couple com-

Body mount separation Chassis frame posed of the equal and opposite forces on the right-hand

B side of the diagram.

The exploded view shows the local loads in the in-

Fig. 16.1-8 Laterally positioned pair of body mountings. dividual members. Member A has vertical loads down-

ward at both ends. These are reacted by the upward force

at point C. This in turn is reacted by an equal and op-

posite force at point C on member B, and the loads in

the overall flexibility (the reciprocal of stiffness) is the member B are a mirror image of those in A.

sum of the individual flexibilities. As a result, the overall Although the overall effect is a torsion carrying

stiffness is lower than that of the individual elements in structure, the individual members (A and B) are subject

the series. Thus,

only to bending and shear forces. Hence it was possible to

use open sections. It is essential that there is a good,

1=K TOTAL ¼ K F-MOUNT þ 1=K BODY þ 1=K R-MOUNT

continuous, bending load path in both members A and B

at point C (point of maximum bending moment).

where K ¼ torsion stiffness and 1/K ¼ torsional flexibility. By the mid-1930s, the need for reasonable torsion

Since the body-plus-mountings assembly was, struc- stiffness was well recognized. A paper of the time from

turally, still in parallel with the chassis, the effect of the which Fig. 16.1-10 is taken, gives overall torsion stiff-

reduced stiffness was to reduce the proportion of the ness values between 1000 and 1750 N m/deg. for vari-

torsion load carried by the body. ous cruciform-braced chassis frames. One of the best of

(b) The converse of the approach in (a) was to stiffen the cruciform-braced underfloor open section chassis

the chassis frame, thus encouraging it to carry was that of the Lagonda V12 of the late 1930s. The

more of the load. Open section, riveted chassis frame consisted entirely of a substantial cross brace,

frame technology was still the norm in the 1930s, with only small tie rods along the side to prevent

and so a method of increasing torsion stiffness, but ‘wracking’ distortion. Its torsion stiffness was measured

still using open section members, was needed. to be a little over 2000 N m/deg.

Body

K F-MOUNT

K BODY

K R-MOUNT

F-mounts

K CHASSIS

R-mounts

Chassis

Fig. 16.1-9 Body and body mounts in series in torsion.

532