Page 628 - Automotive Engineering Powertrain Chassis System and Vehicle Body

P. 628

1

¼

steel

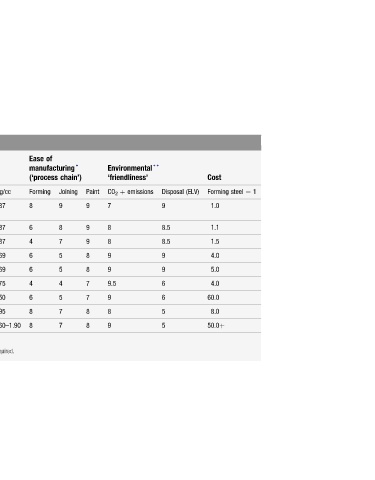

Cost Forming 1.0 1.1 1.5 4.0 5.0 4.0 60.0 8.0 50.0þ

(ELV)

Disposal 9 8.5 8.5 9 9 6 6 5 5

Environmental )) ‘friendliness’ emissions þ

Paint CO 2 7 9 8 9 8 9 9 8 9 8 9.5 7 9 7 8 8 9 8

manufacturing ) chain’) Joining 9 8 7 5 5 4 5 7 7

of (‘process

Ease Forming 8 6 4 6 6 4 6 8 8

g/cc 1.60–1.90 required.

D 7.87 7.87 7.87 2.69 2.69 1.75 4.50 1.95

materials GPa development

body E.Mod 210 210 210 69 69 45 110 40 120–250 extensive

automotive min% <2.0 <2.0 [ 1

of A 80 40 26 5 23 24 7 5 problems. difficulty,

selection MPa min min 1350–1550 min min min min 400–1800 1200–2250 without

realistic parameters UTS 270 400 240 250 240 924 production few [ 10

for MPa min min 1050–1250 min min min min [ met: be

ratings Design YS 140 300 110 120 160 880 950 1100 10 can

and Z þ process, to legislation

criteria steel Z þ H300YD composite difficult

Main grade DCO4 10292 martensitic 5xxx 6xxx sheet sheet [ 1 prevailing

18.2-3 Forming 10130 EN – Aluminium Aluminium Magnesium Titanium fibre range on which with

Table Material Criteria 1. EN HSS 2. UHSS 3. 4. 5. 6. 7. GRP 8. Carbon 9. * Based ** Ease