Page 631 - Automotive Engineering Powertrain Chassis System and Vehicle Body

P. 631

Materials for consideration and use in automotive body structures C HAPTER 18.2

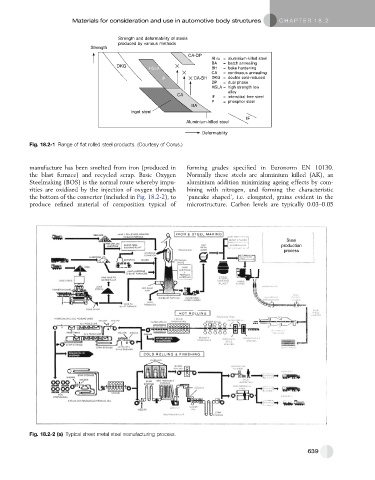

Strength and deformability of steels

produced by various methods

Strength

CA-DP

Al ru = aluminium-killed steel

BA = batch annealing

DKG

HSLA BH = bake hardening

CA = continuous annealing

P CA-BH DKG = double cold-reduced

DP = dual phase

HSLA = high strength low

alloy

CA

IF = interstitial free steel

P = phosphor steel

BA

Ingot steel

IF

Aluminium-killed steel

Deformability

Fig. 18.2-1 Range of flat rolled steel products. (Courtesy of Corus.)

manufacture has been smelted from iron (produced in forming grades specified in Euronorm EN 10130.

the blast furnace) and recycled scrap. Basic Oxygen Normally these steels are aluminium killed (AK), an

Steelmaking (BOS) is the normal route whereby impu- aluminium addition minimizing ageing effects by com-

rities are oxidized by the injection of oxygen through bining with nitrogen, and forming the characteristic

the bottom of the converter (included in Fig. 18.2-2), to ‘pancake shaped’, i.e. elongated, grains evident in the

produce refined material of composition typical of microstructure. Carbon levels are typically 0.03–0.05

Steel

production

process

Fig. 18.2-2 (a) Typical sheet metal steel manufacturing process.

639