Page 632 - Automotive Engineering Powertrain Chassis System and Vehicle Body

P. 632

CHAP TER 1 8. 2 Materials for consideration and use in automotive body structures

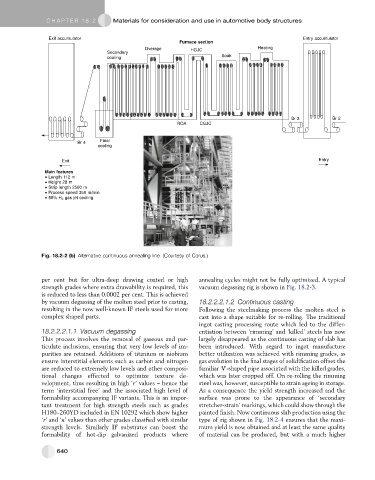

Exit accumulator Entry accumulator

Furnace section

Overage HGJC Heating

Secondary

cooling Soak

Br 3 Br 2

ROA CGJC

Final

Br 4

cooling

Exit Entry

Main features

• Length 112 m

• Height 28 m

• Strip length 2500 m

• Process speed 350 m/min

• 50% H 2 gas jet cooling

Fig. 18.2-2 (b) Alternative continuous annealing line. (Courtesy of Corus.)

per cent but for ultra-deep drawing coated or high annealing cycles might not be fully optimized. A typical

strength grades where extra drawability is required, this vacuum degassing rig is shown in Fig. 18.2-3.

is reduced to less than 0.0002 per cent. This is achieved

by vacuum degassing of the molten steel prior to casting, 18.2.2.2.1.2 Continuous casting

resulting in the now well-known IF steels used for more Following the steelmaking process the molten steel is

complex shaped parts. cast into a shape suitable for re-rolling. The traditional

ingot casting processing route which led to the differ-

18.2.2.2.1.1 Vacuum degassing entiation between ‘rimming’ and ‘killed’ steels has now

This process involves the removal of gaseous and par- largely disappeared as the continuous casting of slab has

ticulate inclusions, ensuring that very low levels of im- been introduced. With regard to ingot manufacture

purities are retained. Additions of titanium or niobium better utilization was achieved with rimming grades, as

ensure interstitial elements such as carbon and nitrogen gas evolution in the final stages of solidification offset the

are reduced to extremely low levels and other composi- familiar ‘V’-shaped pipe associated with the killed grades,

tional changes effected to optimize texture de- which was later cropped off. On re-rolling the rimming

velopment, thus resulting in high ‘r’ values – hence the steel was, however, susceptible to strain ageing in storage.

term ‘interstitial free’ and the associated high level of As a consequence the yield strength increased and the

formability accompanying IF variants. This is an impor- surface was prone to the appearance of ‘secondary

tant treatment for high strength steels such as grades stretcher-strain’ markings, which could show through the

H180–260YD included in EN 10292 which show higher painted finish. Now continuous slab production using the

‘r’ and ‘n’ values than other grades classified with similar type of rig shown in Fig. 18.2-4 ensures that the maxi-

strength levels. Similarly IF substrates can boost the mum yield is now obtained and at least the same quality

formability of hot-dip galvanized products where of material can be produced, but with a much higher

640