Page 633 - Automotive Engineering Powertrain Chassis System and Vehicle Body

P. 633

Materials for consideration and use in automotive body structures C HAPTER 18.2

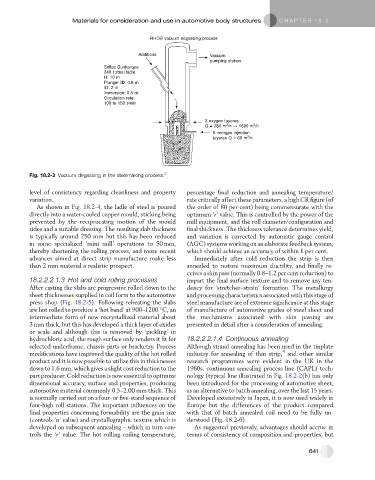

RHOB vacuum degassing process

Additions Vacuum

pumping station

Sollac Dunkerque

240 t steel ladle

H: 10 m

Plunger ID: 0.6 m

ID: 2 m

Immersion: 0.5 m

Circulation rate:

100 to 150 t/min

2 oxygen tuyeres

3

3

Q = 280 m /h → 1600 m /h

8 intergas injection

3

tuyeres Q = 60 m /h

Fig. 18.2-3 Vacuum degassing in the steelmaking process. 3

level of consistency regarding cleanliness and property percentage final reduction and annealing temperature/

variation. rate critically affect these parameters, a high CR figure (of

As shown in Fig. 18.2-4, the ladle of steel is poured the order of 80 per cent) being commensurate with the

directly into a water-cooled copper mould, sticking being optimum ‘r’ value. This is controlled by the power of the

prevented by the reciprocating motion of the mould mill equipment, and the roll diameter/configuration and

sides and a suitable dressing. The resulting slab thickness final thickness. The thickness tolerance determines yield,

is typically around 250 mm but this has been reduced and variation is corrected by automatic gauge control

in some specialized ‘mini mill’ operations to 50 mm, (AGC) systems working on an elaborate feedback system,

thereby shortening the rolling process, and more recent which should achieve an accuracy of within 1 per cent.

advances aimed at direct strip manufacture make less Immediately after cold reduction the strip is then

than 2 mm material a realistic prospect. annealed to restore maximum ductility, and finally re-

ceives a skin pass (normally 0.8–1.2 per cent reduction) to

18.2.2.2.1.3 Hot and cold rolling processes impart the final surface texture and to remove any ten-

After casting the slabs are progressive rolled down to the dency for ‘stretcher–strain’ formation. The metallurgy

sheet thicknesses supplied in coil form to the automotive and processing characteristics associated with this stage of

press shop (Fig. 18.2-5). Following reheating the slabs steel manufacture are of extreme significance at this stage

are hot rolled to produce a ‘hot band’ at 900–1200 C, an of manufacture of automotive grades of steel sheet and

intermediate form of now recrystallized material about the mechanisms associated with skin passing are

3 mm thick, but this has developed a thick layer of oxides presented in detail after a consideration of annealing.

or scale and although this is removed by ‘pickling’ in

hydrochloric acid, the rough surface only renders it fit for 18.2.2.2.1.4 Continuous annealing

selected underframe, chassis parts or bracketry. Process Although strand annealing has been used in the tinplate

4

modifications have improved the quality of the hot rolled industry for annealing of thin strip, and other similar

product and it is now possible to utilize this in thicknesses research programmes were evident in the UK in the

down to 1.6 mm, which gives a slight cost reduction to the 1960s, continuous annealing process line (CAPL) tech-

part producer. Cold reduction is now essential to optimize nology (typical line illustrated in Fig. 18.2-2(b) has only

dimensional accuracy, surface and properties, producing been introduced for the processing of automotive sheet,

automotive material commonly 0.5–2.00 mm thick. This as an alternative to batch annealing, over the last 15 years.

is normally carried out on a four- or five-stand sequence of Developed extensively in Japan, it is now used widely in

four-high roll stations. The important influences on the Europe but the differences of the product compared

final properties concerning formability are the grain size with that of batch annealed coil need to be fully un-

(controls ‘n’ value) and crystallographic texture which is derstood (Fig. 18.2-6).

developed on subsequent annealing – which in turn con- As suggested previously, advantages should accrue in

trols the ‘r’ value. The hot rolling coiling temperature, terms of consistency of composition and properties, but

641