Page 782 - Automotive Engineering Powertrain Chassis System and Vehicle Body

P. 782

Automotive instrumentation and telematics C HAPTER 23.1

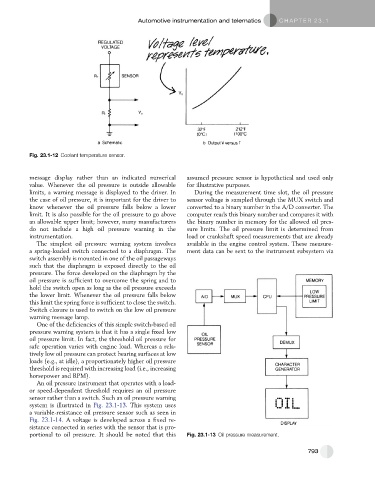

Fig. 23.1-12 Coolant temperature sensor.

message display rather than an indicated numerical assumed pressure sensor is hypothetical and used only

value. Whenever the oil pressure is outside allowable for illustrative purposes.

limits, a warning message is displayed to the driver. In During the measurement time slot, the oil pressure

the case of oil pressure, it is important for the driver to sensor voltage is sampled through the MUX switch and

know whenever the oil pressure falls below a lower converted to a binary number in the A/D converter. The

limit. It is also possible for the oil pressure to go above computer reads this binary number and compares it with

an allowable upper limit; however, many manufacturers the binary number in memory for the allowed oil pres-

do not include a high oil pressure warning in the sure limits. The oil pressure limit is determined from

instrumentation. load or crankshaft speed measurements that are already

The simplest oil pressure warning system involves available in the engine control system. These measure-

a spring-loaded switch connected to a diaphragm. The ment data can be sent to the instrument subsystem via

switch assembly is mounted in one of the oil passageways

such that the diaphragm is exposed directly to the oil

pressure. The force developed on the diaphragm by the

oil pressure is sufficient to overcome the spring and to

hold the switch open as long as the oil pressure exceeds

the lower limit. Whenever the oil pressure falls below

this limit the spring force is sufficient to close the switch.

Switch closure is used to switch on the low oil pressure

warning message lamp.

One of the deficiencies of this simple switch-based oil

pressure warning system is that it has a single fixed low

oil pressure limit. In fact, the threshold oil pressure for

safe operation varies with engine load. Whereas a rela-

tively low oil pressure can protect bearing surfaces at low

loads (e.g., at idle), a proportionately higher oil pressure

threshold is required with increasing load (i.e., increasing

horsepower and RPM).

An oil pressure instrument that operates with a load-

or speed-dependent threshold requires an oil pressure

sensor rather than a switch. Such an oil pressure warning

system is illustrated in Fig. 23.1-13. This system uses

a variable-resistance oil pressure sensor such as seen in

Fig. 23.1-14. A voltage is developed across a fixed re-

sistance connected in series with the sensor that is pro-

portional to oil pressure. It should be noted that this Fig. 23.1-13 Oil pressure measurement.

793