Page 124 - Automotive Engineering

P. 124

Transmissions and driveline CHAPTER 5.1

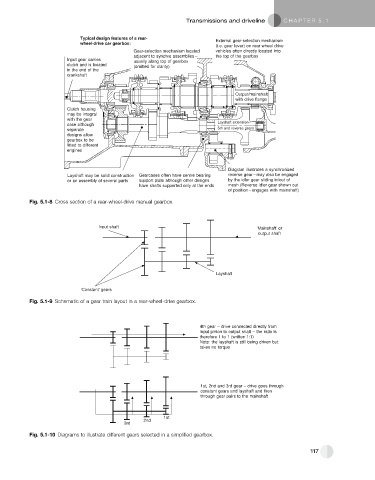

Typical design features of a rear- External gear-selection mechanism

wheel-drive car gearbox:

(i.e. gear lever) on rear wheel drive

Gear-selection mechanism located vehicles often directly located into

adjacent to synchro assemblies – the top of the gearbox

Input gear carries

usually along top of gearbox

clutch and is located (omitted for clarity)

in the end of the

crankshaft

Output/mainshaft

with drive flange

Clutch housing

may be integral

with the gear

case although Layshaft extension–

separate 5th and reverse gears

designs allow

gearbox to be

fitted to different

engines

Diagram illustrates a synchronized

Layshaft may be solid construction Gearcases often have centre bearing reverse gear – may also be engaged

or an assembly of several parts support plate although other designs by the idler gear sliding in/out of

have shafts supported only at the ends mesh (Reverse idler gear shown out

of position – engages with mainshaft)

Fig. 5.1-8 Cross section of a rear-wheel-drive manual gearbox.

Input shaft ‘Mainshaft’ or

output shaft

Layshaft

‘Constant’ gears

Fig. 5.1-9 Schematic of a gear train layout in a rear-wheel-drive gearbox.

4th gear – drive connected directly from

input pinion to output shaft – the ratio is

therefore 1 to 1 (written 1:1)

Note: the layshaft is still being driven but

takes no torque

1st, 2nd and 3rd gear – drive goes through

constant gears and layshaft and then

through gear pairs to the mainshaft

1st

2nd

3rd

Fig. 5.1-10 Diagrams to illustrate different gears selected in a simplified gearbox.

117