Page 53 - Automotive Engineering

P. 53

CH AP TER 2 .1 Measurement of torque, power, speed and fuel consumption

There is no safe alternative, when confronted with an starting severe transient torques can arise. These have

engine of which the characteristics differ significantly from been known to result in the failure of flexible couplings of

any run previously on a given test bed, to following through apparently adequate torque capacity. The maximum

this design procedure. torque that can be necessary to get a green engine over

t.d.c. or that can be generated at first firing should be

2.1a.10.1 An alternative solution estimated and checked against maximum coupling

capacity.

The above worked example makes use of two multiple- Irregular running or imbalance between the powers

bush type rubber couplings with a solid intermediate generated by individual cylinders can give rise to exciting

shaft. An alternative is to make use of a conventional torque harmonics of lower order than expected in

propeller shaft with two universal joints, as used in road a multicylinder engine and should be borne in mind as

vehicles, with the addition of a coupling incorporating an a possible source of rough running. Finally, there is the

annular rubber element in shear to give the necessary possibility of momentary torque reversal when the

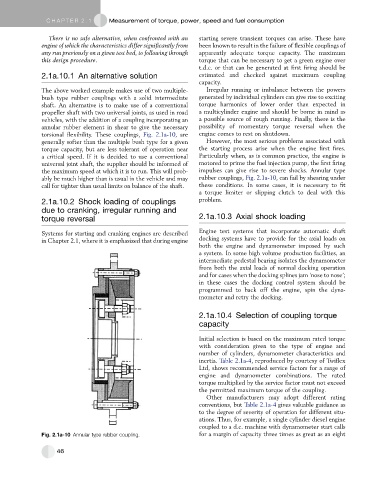

torsional flexibility. These couplings, Fig. 2.1a-10, are engine comes to rest on shutdown.

generally softer than the multiple bush type for a given However, the most serious problems associated with

torque capacity, but are less tolerant of operation near the starting process arise when the engine first fires.

a critical speed. If it is decided to use a conventional Particularly when, as is common practice, the engine is

universal joint shaft, the supplier should be informed of motored to prime the fuel injection pump, the first firing

the maximum speed at which it is to run. This will prob- impulses can give rise to severe shocks. Annular type

ably be much higher than is usual in the vehicle and may rubber couplings, Fig. 2.1a-10, can fail by shearing under

call for tighter than usual limits on balance of the shaft. these conditions. In some cases, it is necessary to fit

a torque limiter or slipping clutch to deal with this

2.1a.10.2 Shock loading of couplings problem.

due to cranking, irregular running and

torque reversal 2.1a.10.3 Axial shock loading

Systems for starting and cranking engines are described Engine test systems that incorporate automatic shaft

in Chapter 2.1, where it is emphasized that during engine docking systems have to provide for the axial loads on

both the engine and dynamometer imposed by such

a system. In some high volume production facilities, an

intermediate pedestal bearing isolates the dynamometer

from both the axial loads of normal docking operation

and for cases when the docking splines jam ‘nose to nose’;

in these cases the docking control system should be

programmed to back off the engine, spin the dyna-

mometer and retry the docking.

2.1a.10.4 Selection of coupling torque

capacity

Initial selection is based on the maximum rated torque

with consideration given to the type of engine and

number of cylinders, dynamometer characteristics and

inertia. Table 2.1a-4, reproduced by courtesy of Twiflex

Ltd, shows recommended service factors for a range of

engine and dynamometer combinations. The rated

torque multiplied by the service factor must not exceed

the permitted maximum torque of the coupling.

Other manufacturers may adopt different rating

conventions, but Table 2.1a-4 gives valuable guidance as

to the degree of severity of operation for different situ-

ations. Thus, for example, a single cylinder diesel engine

coupled to a d.c. machine with dynamometer start calls

Fig. 2.1a-10 Annular type rubber coupling. for a margin of capacity three times as great as an eight

46