Page 50 - Automotive Engineering

P. 50

Measurement of torque, power, speed and fuel consumption CHAPTER 2.1

These differ in three important respects from those

of, say, a steel shaft in torsion:

1. The coupling does not obey Hooke’s law: the stiff-

ness or coupling rate C c ¼ DT/Dq increases with

torque. This is partly an inherent property of the

rubber and partly a consequence of the way it is

constrained.

2. The shape of the torque–deflection curve is not in-

dependent of frequency. Dynamic torsional charac-

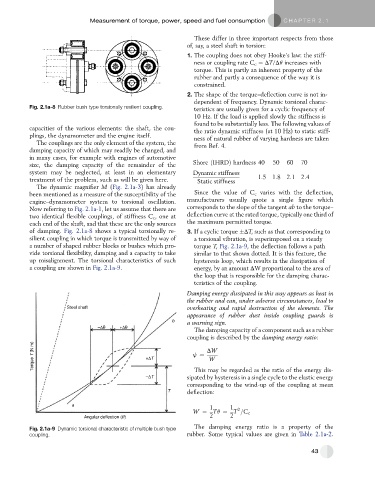

Fig. 2.1a-8 Rubber bush type torsionally resilient coupling. teristics are usually given for a cyclic frequency of

10 Hz. If the load is applied slowly the stiffness is

found to be substantially less. The following values of

capacities of the various elements: the shaft, the cou- the ratio dynamic stiffness (at 10 Hz) to static stiff-

plings, the dynamometer and the engine itself. ness of natural rubber of varying hardness are taken

The couplings are the only element of the system, the from Ref. 4.

damping capacity of which may readily be changed, and

in many cases, for example with engines of automotive

size, the damping capacity of the remainder of the Shore ðIHRDÞ hardness 40 50 60 70

system may be neglected, at least in an elementary Dynamic stiffness

treatment of the problem, such as will be given here. Static stiffness 1:5 1:8 2:1 2:4

The dynamic magnifier M (Fig. 2.1a-3) has already

been mentioned as a measure of the susceptibility of the Since the value of C c varies with the deflection,

engine–dynamometer system to torsional oscillation. manufacturers usually quote a single figure which

Now referring to Fig. 2.1a-1, let us assume that there are corresponds to the slope of the tangent ab to the torque–

two identical flexible couplings, of stiffness C c , one at deflection curve at the rated torque, typically one third of

each end of the shaft, and that these are the only sources the maximum permitted torque.

of damping. Fig. 2.1a-8 shows a typical torsionally re- 3. If a cyclic torque DT, such as that corresponding to

silient coupling in which torque is transmitted by way of a torsional vibration, is superimposed on a steady

a number of shaped rubber blocks or bushes which pro- torque T, Fig. 2.1a-9, the deflection follows a path

vide torsional flexibility, damping and a capacity to take similar to that shown dotted. It is this feature, the

up misalignment. The torsional characteristics of such hysteresis loop, which results in the dissipation of

a coupling are shown in Fig. 2.1a-9. energy, by an amount DW proportional to the area of

the loop that is responsible for the damping charac-

teristics of the coupling.

Damping energy dissipated in this way appears as heat in

the rubber and can, under adverse circumstances, lead to

Steel shaft overheating and rapid destruction of the elements. The

appearance of rubber dust inside coupling guards is

b a warning sign.

–Δθ +Δθ

The damping capacity of a component such as a rubber

coupling is described by the damping energy ratio:

Torque T (N m) +ΔT j ¼ DW

W

This may be regarded as the ratio of the energy dis-

–ΔT sipated by hysteresis in a single cycle to the elastic energy

corresponding to the wind-up of the coupling at mean

T deflection:

a

1 1

2

W ¼ Tq ¼ T =C c

Angular deflection ( ) 2 2

Fig. 2.1a-9 Dynamic torsional characteristic of multiple bush type The damping energy ratio is a property of the

coupling. rubber. Some typical values are given in Table 2.1a-2.

43