Page 130 - Battery Reference Book

P. 130

4/14 Nickel batteries

presently developed technology offers to the user a bat-

tery with high specific energy, low maintenance, deep

discharge capability and long cycle life. Full-scale

electrodes have exceeded 1300 deep discharge cycles.

Full-scale cells as well as 6 V modules have been fab-

ricated and show no capacity fade under 100% depth- 2 Charge Discharge

-

of-discharge cycling. Energy efficiencies are typically - Cl5 rate C13 rate

70% or greater (see Table 4.9). 6 0.5

I I I I t

Table 4.9 Nickel-iron battery performance 0 50 100 50 0

State of charge (Om\

1980 to present Goals

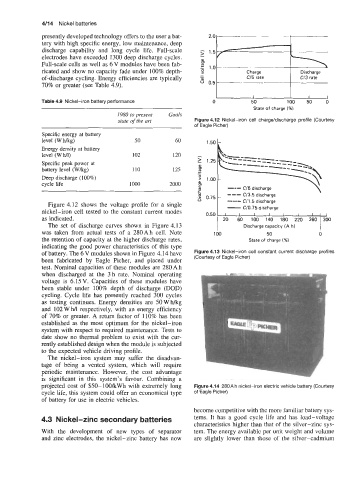

state of the art Figure 4.12 Nickel-iron cell chargeldischarge profile (Courtesy

of Eagle Picher)

Specific energy at battery

level (W hkg) 50 60 1.50 c

Energy density at battery

level (W M) 102 120

Specific peak power at

battery level (Wkg) I10 125

Deep discharge (100%)

cycle life 1000 2000

--- (73.5 discharge

2 0.75

Figure 4.12 shows the voltage profile for a single - --.- C11.5 discharge

- U0.75 discharge

nickel-iron cell tested to the constant current modes

as indicated.

The set of discharge curves shown in Figure 4.13

was taken from actual tests of a 280Ah cell. Note

the retention of capacity at the higher discharge rates,

indicating the good power characteristics of this type

of battery. The 6 V modules shown in Figure 4.14 have

been fabricated by Eagle Picher, and placed under

test. Nominal capacities of these modules are 280 Ah

when discharged at the 3 h rate. Nominal operating

voltage is 6.15V. Capacities of these modules have

been stable under 100% depth of discharge (DOD)

cycling. Cycle life has presently reached 300 cycles

as testing continues. Energy densities are 50 W hkg

and 102 W h/l respectively, with an energy efficiency

of 70% or greater. A return factor of 110% has been

established as the most optimum for the nickel-iron

system with respect to required maintenance. Tests to

date show no thermal problem to exist with the cur-

rently established design when the module is subjected

to the expected vehicle driving profile.

The nickel-iron system may suffer the disadvan-

tage of being a vented system, which will require

periodic maintenance. However, the cost advantage

is significant in this system’s favour. Combining a

projected cost of $50- lOOkWh with extremely long Figure 4.14 280A h nickel-iron electric vehicle battery (Courtesy

cycle life, this system could offer an economical type of Eagle Picher)

of battery for use in electric vehicles.

become competitive with the more familiar battery sys-

4.3 Nickel-zinc secondary batteries tems. It has a good cycle life and has load-voltage

characteristics higher than that of the silver-zinc sys-

With the development of new types of separator tem. The energy available per unit weight and volume

and zinc electrodes, the nickel-zinc battery has now are slightly lower than those of the silver-cadmium