Page 350 - Battery Reference Book

P. 350

Other characteristic curves 30121

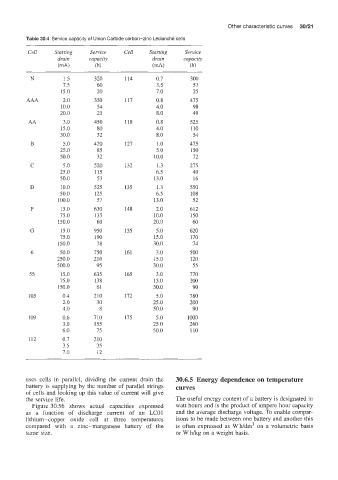

Table 30.4 Service capacity of Union Carbide carbon-zinc Leclanche cells

Cell Starh'ng Service Cell Starting Service

drain capacity drain capacity

WL) (h) (d) (h)

-

N 1.5 320 114 0.7 300

7.5 60 3.5 57

15.0 20 7.0 25

AAA 2.0 350 117 0.8 475

10.0 54 4.0 98

20.0 21 8.0 49

AA 3.0 450 118 0.8 525

15.0 80 4.0 110

30.0 32 8.0 54

B 5.0 420 127 1 .o 475

25.0 85 5 .O 150

50.0 32 10.0 72

C 5.0 520 132 1.3 275

25.0 115 6.5 40

50.0 53 13.0 16

D 10.0 525 135 1.3 550

50.0 125 6.5 108

100.0 57 13.0 52

F 15.0 630 148 2.0 612

75.0 135 10.0 150

150.0 60 20.0 60

G 15.0 950 155 5.0 620

75.0 190 15.0 170

150.0 78 30.0 74

6 50.0 750 161 3.0 500

250.0 210 15.0 120

500.0 95 30.0 55

55 15.0 635 165 3.0 770

75.0 138 15.0 200

150.0 61 30.0 90

105 0.4 210 172 5.0 780

2.0 30 25.0 200

4.0 8 50.0 90

I09 0.6 710 175 5.0 1000

3.0 155 25.0 260

6.0 75 50.0 110

112 0.7 210

3.5 35

7.0 12

uses cells in parallel, dividing the current drain the 30.6.5 Energy dependence on temperature

battery is supplying by the number of parallel strings curves

of cells and looking up this value of current will give

the service life. The useful energy content of a battery is designated in

Figure 30.56 shows actual capacities expressed watt hours and is the product of ampere hour capacity

as a function of discharge current of an LC0l and the average discharge voltage. To enable compar-

lithium-copper oxide cell at three temperatures isons to be made between one battery and another this

compared with a zinc-manganese battery of the is often expressed as W h/dm3 on a volumetric basis

same size. or W hlkg on a weight basis.