Page 317 - Biaxial Multiaxial Fatigue and Fracture

P. 317

The Background of Fatigue Limit Ratio of Torsional Fatigue to Rotating Bending Fatigue in .__ 301

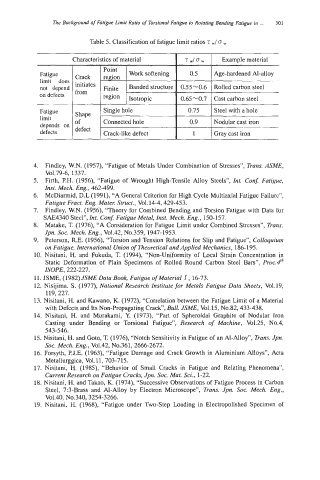

Table 5. Classification of fatigue limit ratios z ,,,/ u

Characteristics of material Z ,,,/ (T I Example material

Fatigue Crack Age-hardened Al-alloy

limit does

not depend initiates

on defects from

0.65-0.7 I Cast carbon steel

Fatigue Shape 0.75 Steel with a hole

limit

depends on of Connected hole 0.9 Nodular cast iron

defects defect Crack-like defect 1 1 Gray cast iron

4. Findley, W.N. (1957), “Fatigue of Metals Under Combination of Stresses”, Trans. ASME,

V01.79-6, 1337.

5. Firth, P.H. (1956), “Fatigue of Wrought High-Tensile Alloy Steels”, Int. Conf Fatigue,

Inst. Mech. Eng., 462-499.

6. McDiarmid, D.L (1991), “A General Criterion for High Cycle Multiaxial Fatigue Failure”,

Fatigue Fract. Eng. Mater. Struct., Vo1.14-4,429-453.

7. Findley, W.N. (1956), “Theory for Combined Bending and Torsion Fatigue with Data for

SAEi4340 Steel”, Int. Con$ Fatigue Metal, Inst. Mech. Eng., 150-157.

8. Matake, T. (1976), “A Consideration for Fatigue Limit under Combined Stresses”, Trans.

Jpn. SOC. Mech. Eng., Vo1.42, No.359, 1947-1953.

9. Peterson, R.E. (1956), “Torsion and Tension Relations for Slip and Fatigue”, Colloquium

on Fatigue, International Union of Theoretical and Applied Mechanics, 186-195.

10. Nisitani, H. and Fukuda, T. (1994), “Non-Uniformity of Local Strain Concentration in

Static Deformation of Plain Specimens of Rolled Round Carbon Steel Bars”, Pr0c.4‘~

ISOPE, 222-227.

11. JSME, (1982) JSME Data Book Fatigue of Material 1, 16-73.

12. Nisijima. S. (1977), National Research Institute for Metals Fatigue Data Sheets, Vo1.19,

119,227.

13. Nisitani, H. and Kawano, K. (1972), “Correlation between the Fatigue Limit of a Material

with Defects and Its Non-Propagating Crack”, Bull. JSME, Vo1.15, No.82,433-438.

14. Nisitani, H. and Murakami, Y. (1973), “Part of Spheroidal Graphite of Nodular Iron

Casting under Bending or Torsional Fatigue”, Research of Machine, Vo1.25, No.4,

543-546.

15. Nisitani, H. and Goto, T. (1976), “Notch Sensitivity in Fatigue of an Al-Alloy”, Trans. Jpn.

SOC. Mech. Eng., Vo1.42, N0.361,2666-2672.

16. Forsyth, P.J.E. (1963), “Fatigue Damage and Crack Growth in Aluminium Alloys”, Acta

Metallurggica, Vol. 11,703-715.

17. Nisitani, H. (1985), “Behavior of Small Cracks in Fatigue and Relating Phenomena”,

Current Research on Fatigue Cracks, Jpn. SOC. Mat. Sci., 1-22.

18. Nisitani, H. and Takao, K. (1974), “Successive Observations of Fatigue Process in Carbon

Steel, 7:3-Brass and Al-Alloy by Electron Microscope”, Trans. Jpn. SOC. Mech. Eng.,

Vo1.40, N0.340,3254-3266.

19. Nisitani, H. (1968), “Fatigue under Two-step Loading in Electropolished Specimen of