Page 313 - Biaxial Multiaxial Fatigue and Fracture

P. 313

The Background of Fatigue Limit Ratio of Torsional Fatigue to Rotating Bending Fatigue in ... 297

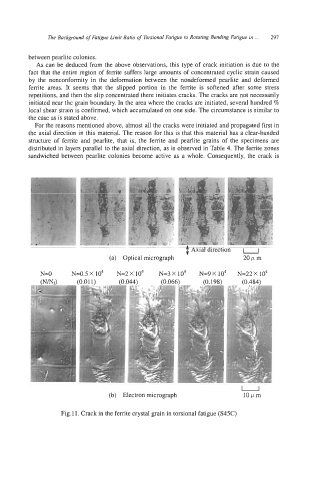

between pearlite colonies.

As can be deduced from the above observations, this type of crack initiation is due to the

fact that the entire region of ferrite suffers large amounts of concentrated cyclic strain caused

by the nonconformity in the deformation between the nondeformed pearlite and deformed

ferrite areas. It seems that the slipped portion in the ferrite is softened after some stress

repetitions, and then the slip concentrated there initiates cracks. The cracks are not necessarily

initiated near the grain boundary. In the area where the cracks are initiated, several hundred %

local shear strain is confirmed, which accumulated on one side. The circumstance is similar to

the case as is stated above.

For the reasons mentioned above, almost all the cracks were initiated and propagated first in

the axial direction in this material. The reason for this is that this material has a clear-banded

structure of ferrite and pearlite, that is, the ferrite and pearlite grains of the specimens are

distributed in layers parallel to the axial direction, as is observed in Table 4. The ferrite zones

sandwiched between pearlite colonies become active as a whole. Consequently, the crack is

I

(a) Optical micrograph 20~

m

N=O N=0.5 X IO4 N=2 X IO4 N=3 X IO4 N=9 X IO4 N=22 X lo4

) ( (0.48

3 ‘4J a’fw\ ”Vi 1.961 ‘9

U

(b) Electron micrograph 10pm

Fig.11. Crack in the ferrite crystal grain in torsional fatigue (S45C)