Page 321 - Biaxial Multiaxial Fatigue and Fracture

P. 321

Influence of Defects on Fatigue Life of Aluminium Pressure Diecastings 305

EXPERIMENTAL ANALYSIS OF DEFECTS

To study the influence of the presence of defects on fatigue life of aluminium pressure

diecastings, two lots of 50 parts each, considered acceptable and unacceptable, were supplied

by a foundry company (SONAFI, Porto, Portugal). The selection was made in accordance to

the foundry internal criteria for the part selected, and using adequate quality control techniques

(visual control, X-Rays, etc.). Figure 1 presents the component selected, with the fatigue test

sample placed in the position from where it was removed.

Fig. 1. Brake pedal in an aluminium diecasting alloy AS9U3 (NF A57-703) [SI with the

fatigue test sample.

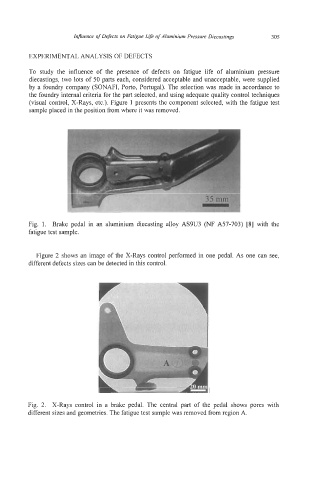

Figure 2 shows an image of the X-Rays control performed in one pedal. As one can see,

different defects sizes can be detected in this control.

Fig. 2. X-Rays control in a brake pedal. The central part of the pedal shows pores with

different sizes and geometries. The fatigue test sample was removed from region A.