Page 325 - Biaxial Multiaxial Fatigue and Fracture

P. 325

Influence of Defects on Fatigue Life of Aluminium Pressure Diecastings 309

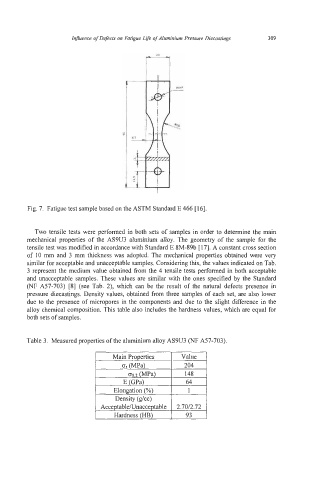

Fig. 7. Fatigue test sample based on the ASTM Standard E 466 [16].

Two tensile tests were performed in both sets of samples in order to determine the main

mechanical properties of the AS9U3 aluminium alloy. The geometry of the sample for the

tensile test was modified in accordance with Standard E 8M-89b [17]. A constant cross section

of 10 mm and 3 mm thickness was adopted. The mechanical properties obtained were very

similar for acceptable and unacceptable samples. Considering this, the values indicated on Tab.

3 represent the medium value obtained from the 4 tensile tests performed in both acceptable

and unacceptable samples. These values are similar with the ones specified by the Standard

(NF A57-703) [8] (see Tab. 2), which can be the result of the natural defects presence in

pressure diecastings. Density values, obtained from three samples of each set, are also lower

due to the presence of micropores in the components and due to the slight difference in the

alloy chemical composition. This table also includes the hardness values, which are equal for

both sets of samples.

Table 3. Measured properties of the aluminium alloy AS9U3 (NF A57-703).

Main Properties Value

or (MPa) 204

~30.2 (MPa) 148

E (GPa) 64

Elongation (%) 1

Density (g/cc)

AcceptableNnacceptable 2.7012.72

Hardness (HB) 93