Page 390 - Biaxial Multiaxial Fatigue and Fracture

P. 390

374 M. FONTE ET AL.

DISCUSSION

Studies of the mechanisms governing fatigue behaviour in aluminium alloys rationalised

accelerated crack growth rates in moist media (as compared to those in vacuum or inert

environments) in terms of conventional corrosion fatigue processes such anodic dissolution

and/or hydrogen embrittlement [26,50,]. Apart from environmental effects, certain intrinsic

metallurgical phenomena, in particular those related to slip characteristics, are also considered

to cause pronounced differences in near-threshold crack growth behaviour between different

alloys. In addition to environment and microstructurally influenced growth mechanisms,

crack closure processes can significantly affect fatigue behaviour in the near-threshold regime

[8,18,32].

Microstructural features directly influence material properties. The toughness, for

example, may be reduced by large fractions of GB precipitates produced by inefficient

quenching and by aging [14,18,19,22]. The concept of strain localisation in planar slip bands

appears to be significant in both monotonic and fatigue testing.

Environment and microstructure also strongly influence the fatigue crack growth

resistance of high strength aluminium alloys [57] with crack deflection and branching leading

to important consequences for the mechanical behaviour [ 101. Local microstructure and the

applied AK primarily control the slip mode being responsible for crack propagation. In

addition, crack advance can be significantly altered by the presence of the environment [Sl].

As a result, both microstructural and environmental factors have a strong effect on the near

threshold fatigue crack growth behaviour.

Aiming to contribute for the understanding of these phenomena, the discussion will lay in

these two areas: (a) environment and (b) microstructure via slip characteristics. First of all one

needs to compare the fatigue results in ambient air to the results in vacuum, in order to

distinguish the role of microstructure and environment.

In vacuum, the planar slip alloy exhibits a significant fatigue resistance in comparison

with to the wavy slip OA alloy microstructure shown by the increased threshold in both dK*,h

and x",. Moreover, due to slip reversibility in the UA alloy, both m*th and d, can have

independently different contributions to the crack growth process: crack branching e.g. can

occur in planar slip materials and the crack path can be tortuous, in zigzag, with

crystallographic facets.

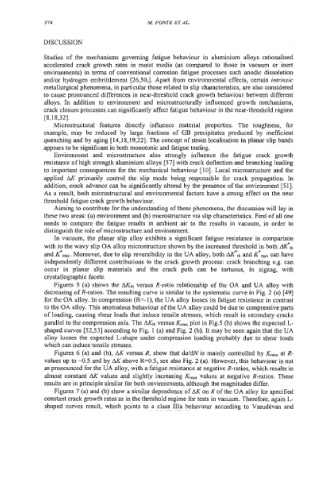

Figures 5 (a) shows the AKh versus R-ratio relationship of the OA and UA alloy with

decreasing of R-ratios. The resulting curve is similar to the systematic curve in Fig. 2 (a) [49]

for the OA alloy. In compression (R=-1), the UA alloy looses its fatigue resistance in contrast

to the OA alloy. This anomalous behaviour of the UA alloy could be due to compressive parts

of loading, causing shear loads that induce tensile stresses, which result in secondary cracks

parallel to the compression axis. The hKth versus Kmax plot in Fig.5 (b) shows the expected L-

shaped curves [52,53] according to Fig. 1 (a) and Fig. 2 (b). It may be seen again that the UA

alloy looses the expected L-shape under compression loading probably due to shear loads

which can induce tensile stresses.

Figures 6 (a) and (b), AK versus R, show that dala is mainly controlled by K,, at R-

values up to -0.5 and by AK above R=0.5, see also Fig. 2 (a). However, this behaviour is not

as pronounced for the UA alloy, with a fatigue resistance at negative R-ratios, which results in

almost constant AK values and slightly increasing K- values at negative R-ratios. These

results are in principle similar for both environments, although the magnitudes differ.

Figures 7 (a) and (b) show a similar dependence of AK on R of the OA alloy for specified

constant crack growth rates as in the threshold regime for tests in vacuum. Therefore, again L-

shaped curves result, which points to a class IIIa behaviour according to Vasud6van and