Page 431 - Biaxial Multiaxial Fatigue and Fracture

P. 431

Cyclic Behaviour of a Duplex Stainless Steel Under Multiaxial Loading: Experiments and Modelling 41 5

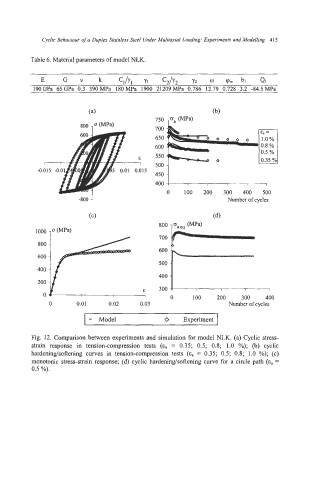

Table 6. Material parameters of model NLK.

~~

E G v k CJY, YI C,/Y, ~2 qm bl QI

190 GPa 65 GPa 0.3 390 MPa 180 MPa 1900 21209 MPa 0.786 12.79 0.728 3.2 -84.5 MPa

700

650

600

550

E

500

7 7

400 k

-0.015 0.015

450

0 100 200 300 400 500

Number of cycles

800

1000

700

800

600

600

500

400

400

200

300

E

0 7 0 100 200 300 400

0 0.01 0.02 0.03 Number of cycles

I - Model 0 Experiment I

Fig. 12. Comparison between experiments and simulation for model NLK. (a) Cyclic stress-

strain response in tension-compression tests (E~ = 0.35; 0.5; 0.8; 1.0 %); (b) cyclic

hardeninglsofiening curves in tension-compression tests (E~ = 0.35; 0.5; 0.8; 1.0 %); (c)

monotonic stress-strain response; (d) cyclic hardeningkofiening curve for a circle path (E~ =

0.5 %).