Page 433 - Biaxial Multiaxial Fatigue and Fracture

P. 433

Cyclic Behaviour of a Duplex Stainless Steel Under Multiaxial Loading: Experiments and Modelling 417

Table 8. Material parameters of model NP2.

E G V k C,/Y1 Yl C,/Y, Y2 0 0.0

190GPa 65GPa 0.3 390MPa 180MPa 1900 21209MPa 0.786 12.79 0.728

bi QI Y3 cx/y3 Cm/Y3 co OX Qx qx n

3.2 -84.5MPa 200 50MPa 570MPa OMPa 3.2 100 0.2 10

-800 J

-800 ’ 1

(e) (f)

440 oaeq (MW

800 420 1

750

700 400

650

600

500

450 4 320 i!!k 300

400 i I

0 100 200 300 400 0 100 200 300 400 500

Number of cycles Number of cycles

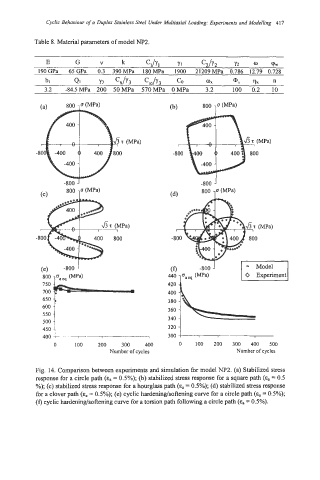

Fig. 14. Comparison between experiments and simulation for model NP2. (a) Stabilized stress

response for a circle path (Ea = 0.5%); (b) stabilized stress response for a square path (sa = 0.5

%); (c) stabilized stress response for a hourglass path (E~.= 0.5%); (d) stabilized stress response

for a clover path = 0.5%); (e) cyclic hardeningkoftening curve for a circle path = 0.5%);

(f) cyclic hardeningsoftening curve for a torsion path following a circle path (sa = 0.5%).