Page 434 - Biaxial Multiaxial Fatigue and Fracture

P. 434

418 AUBIN I? QUAEGEBEUR AND S. DEGALLALX

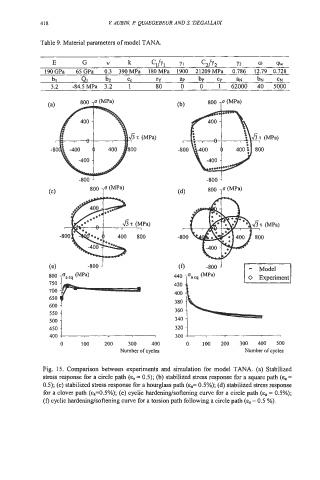

Table 9. Material parameters of model TANA.

E G V CIlYl Y' C2h2 YZ CP..

190GPa 65GPa 0.3 390h4Pa 180MPa 1900 21209MF'a 0.786 12.79 0.728

bi Q1 b2 cc ry ap bp CP aN bN CN

3.2 -84.5 MPa 3.2 1 80 0 0 1 62000 40 5000

@)

7

-800

(MPa) &T (MPa)

-1 1

800 800

-800 (0

420 f 0 Experiment

440

eq

400

300 1

320

0 100 200 300 400 0 100 200 300 400 500

Number of cycles Number of cycles

Fig. 15. Comparison between experiments and simulation for model TANA. (a) Stabilized

stress response for a circle path (Ea = 0.5); (b) stabilized stress response for a square path (E~ =

0.5); (c) stabilized stress response for a hourglass path (sa= 0.5%); (d) stabilized stress response

for a clover path (€a=0.5%); (e) cyclic hardeninglsoftening curve for a circle path = 0.5%);

(0 cyclic hardeninglsofiening curve for a torsion path following a circle path (&= 0.5 %).