Page 458 - Biaxial Multiaxial Fatigue and Fracture

P. 458

442 M. WEICK AND 1 AKTAA

stresses system, slip bands are activated in all directions. Hence, preferred directions of the

orientation of cracks cannot be expected. Consequently, it is impossible in this case to

determine an explicit correlation between the phase shift and fatigue.

With our biaxial machine the multiaxial loading was generated as follows: While the load

in axial direction is raised by a conventional tension feature, the circumferential strain is

generated by a pressure difference of the surrounding media. The advantage of this method are

the fixed directions of principal stresses and strains during the non-proportional loading cycles.

Thus, the orientation of a crack can be assigned to the directions of principal stresses.

To obtain information about the microcrack nucleation and propagation, we use a sonic

emission system which records the current sonic emissions during the experiment. From these

signals, conclusions are drawn with regard to the propagation behaviour of microcracks under

multiaxial loading.

With the developed microcrack model we calculate the lifetime on the basis of the

experimental obtained AJ's. To verify this model we compare the results to the measured life-

time of the specimens.

EXPERIMENTAL DETAILS

Test facili5

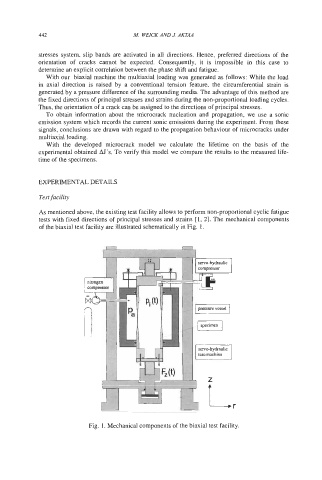

As mentioned above, the existing test facility allows to perform non-proportional cyclic fatigue

tests with fixed directions of principal stresses and strains [ 1, 21. The mechanical components

of the biaxial test facility are illustrated schematically in Fig. 1.

Fig. 1. Mechanical components of the biaxial test facility.