Page 61 - Biaxial Multiaxial Fatigue and Fracture

P. 61

46 E LABESSE-JIED ET AL

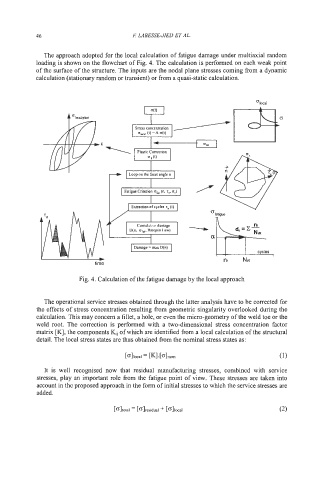

The approach adopted for the local calculation of fatigue damage under multiaxial random

loading is shown on the flowchart of Fig. 4. The calculation is performed on each weak point

of the surface of the structure. The inputs are the nodal plane stresses coming from a dynamic

calculation (stationary random or transient) or from a quasi-static calculation.

/

t ace5 1

E

Fatigue Criterion ah, (n, T", an)

- I'

D(n, of*, Basquin Law)

Damage = max D(n)

time

Fig. 4. Calculation of the fatigue damage by the local approach

The operational service stresses obtained through the latter analysis have to be corrected for

the effects of stress concentration resulting from geometric singularity overlooked during the

calculation. This may concern a fillet, a hole, or even the micro-geometry of the weld toe or the

weld root. The correction is performed with a two-dimensional stress concentration factor

matrix [K], the components Ki, of which are identified from a local calculation of the structural

detail. The local stress states are thus obtained from the nominal stress states as:

It is well recognised now that residual manufacturing stresses, combined with service

stresses, play an important role from the fatigue point of view. These stresses are taken into

account in the proposed approach in the form of initial stresses to which the service stresses are

added.