Page 59 - Biaxial Multiaxial Fatigue and Fracture

P. 59

44 E LABESSE-JIED ET AL.

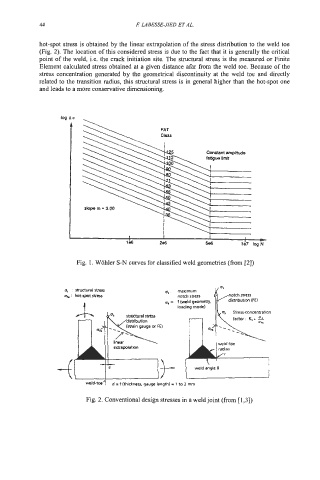

hot-spot stress is obtained by the linear extrapolation of the stress distribution to the weld toe

(Fig. 2). The location of this considered stress is due to the fact that it is generally the critical

point of the weld, i.e. the crack initiation site. The structural stress is the measured or Finite

Element calculated stress obtained at a given distance afar from the weld toe. Because of the

stress concentration generated by the geometrical discontinuity at the weld toe and directly

related to the transition radius, this structural stress is in general higher than the hot-spot one

and leads to a more conservative dimensioning.

4

le7

IogN

Fig. 1. Wohler S-N curves for classified weld geometries (from [2])

loading mode)

II, 0, Stress<oncenvation

fador : K,= 3

(strain gauge or FE)

1 linear

i,

weld-toe

extrapolatm

I -w I -L i

1

weld angle e

~ l d - t ~ ~

d I (thickness. gauge length) - 1 lo 2 mm

f

Fig. 2. Conventional design stresses in a weld joint (from [1,3])