Page 197 - Biofuels Refining and Performance

P. 197

180 Chapter Six

generally much more effective than acid catalysts. The reaction was

performed successfully at both 45 C and 60 C in 4 h, with the production

of 97% of ME.

Kruclen et al. [40] have presented a process for conversion of a high-

melting point palm oil fraction into ethyl esters, which could be used as a

diesel fuel substitute. The amount of catalyst used (KOH) was 0.1–1%, and

the reaction was completed rapidly at 80 C with yields of 80–94%, depend-

ing on the concentration of catalysts. The specific gravity of ethyl ester

varied from 0.847 to 0.864 with kinematic viscosity of 4.4–4.6 cSt at 40 C.

Gelbard et al. [41] have determined the yield of transesterification of

1

rapeseed oil with methanol and base by H-NMR (nuclear magnetic

resonance) spectroscopy. The relevant signals chosen for integration

are those of methoxy groups in ME at 3.7 ppm (parts per million) (sin-

glet) and of the -carbonyl methylene groups present in all fatty ester

derivatives at 2.3 ppm. The latter appears as a triplet, so accurate meas-

urements require good separation of this multiple at 2.1 ppm, which is

related to allylic protons.

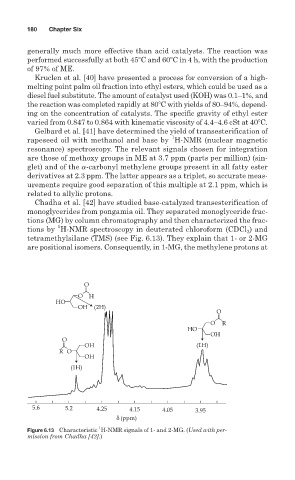

Chadha et al. [42] have studied base-catalyzed transesterification of

monoglycerides from pongamia oil. They separated monoglyceride frac-

tions (MG) by column chromatography and then characterized the frac-

1

tions by H-NMR spectroscopy in deuterated chloroform (CDCl ) and

3

tetramethylsilane (TMS) (see Fig. 6.13). They explain that 1- or 2-MG

are positional isomers. Consequently, in 1-MG, the methylene protons at

O

O H

HO

OH (2H)

O

O R

HO

OH

O

OH (1H)

R O

OH

(1H)

5.6 5.2 4.25 4.15 4.05 3.95

δ (ppm)

1

Figure 6.13 Characteristic H-NMR signals of 1- and 2-MG. (Used with per-

mission from Chadha [42].)