Page 240 - Biofuels Refining and Performance

P. 240

Cracking of Lipids for Fuels and Chemicals 223

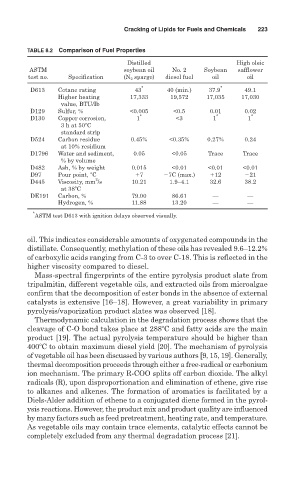

TABLE 8.2 Comparison of Fuel Properties

Distilled High oleic

ASTM soybean oil No. 2 Soybean safflower

test no. Specification (N 2 sparge) diesel fuel oil oil

D613 Cetane rating 43 * 40 (min.) 37.9 * 49.1

Higher heating 17,333 19,572 17,035 17,030

value, BTU/Ib

D129 Sulfur, % <0.005 <0.5 0.01 0.02

D130 Copper corrosion, 1 * <3 1 * 1 *

3 h at 50 C

standard strip

D524 Carbon residue 0.45% <0.35% 0.27% 0.24

at 10% residium

D1796 Water and sediment, 0.05 <0.05 Trace Trace

% by volume

D482 Ash, % by weight 0.015 <0.01 <0.01 <0.01

D97 Pour point, C 7 7C (max.) 12 21

2

D445 Viscosity, mm /s 10.21 1.9–4.1 32.6 38.2

at 38 C

DE191 Carbon, % 79.00 86.61 — —

Hydrogen, % 11.88 13.20 — —

*

ASTM test D613 with ignition delays observed visually.

oil. This indicates considerable amounts of oxygenated compounds in the

distillate. Consequently, methylation of these oils has revealed 9.6–12.2%

of carboxylic acids ranging from C-3 to over C-18. This is reflected in the

higher viscosity compared to diesel.

Mass-spectral fingerprints of the entire pyrolysis product slate from

tripalmitin, different vegetable oils, and extracted oils from microalgae

confirm that the decomposition of ester bonds in the absence of external

catalysts is extensive [16–18]. However, a great variability in primary

pyrolysis/vaporization product slates was observed [18].

Thermodynamic calculation in the degradation process shows that the

cleavage of C-O bond takes place at 288 C and fatty acids are the main

product [19]. The actual pyrolysis temperature should be higher than

400 C to obtain maximum diesel yield [20]. The mechanism of pyrolysis

of vegetable oil has been discussed by various authors [9, 15, 19]. Generally,

thermal decomposition proceeds through either a free-radical or carbonium

ion mechanism. The primary R-COO splits off carbon dioxide. The alkyl

radicals (R), upon disproportionation and elimination of ethene, give rise

to alkanes and alkenes. The formation of aromatics is facilitated by a

Diels-Alder addition of ethene to a conjugated diene formed in the pyrol-

ysis reactions. However, the product mix and product quality are influenced

by many factors such as feed pretreatment, heating rate, and temperature.

As vegetable oils may contain trace elements, catalytic effects cannot be

completely excluded from any thermal degradation process [21].