Page 241 - Biofuels Refining and Performance

P. 241

224 Chapter Eight

8.2.1 Catalytic cracking (CC)

In 1979, a paper [22] from the petrochemical industry reported for the

first time that high-molecular-weight triglycerides such as corn oil

(C H 104 O ) and castor oil (C H 104 O ) were convertible to a high-grade

57

9

57

6

gasoline when passed over H-ZSM-5, a catalyst. The latter is a synthetic,

medium-pore, shape-selective acid catalyst. Lipids were fed with a piston

displacement pump at a rate of 2 mL/h with flowing hydrogen (300 mL/h)

over 2 mL of H-ZSM-5 catalyst (0.77 g, 14–30 mesh) contained in a ver-

tical Pyrex reactor at atmospheric pressure and T 400–450 C.

Paraffins, olefins, aromatics, and nonaromatics could be detected in the

product mixture. The distribution of hydrocarbons is similar to selective

conversion of methanol into hydrocarbon units with up to 10 carbon

atoms per molecule. In all cases, a high degree of BTX aromatics (ben-

zene, toluene, and xylene) was achieved. The precondition for the catalytic

conversion is that the molecule penetrate the cavities of microporous

zeolite.

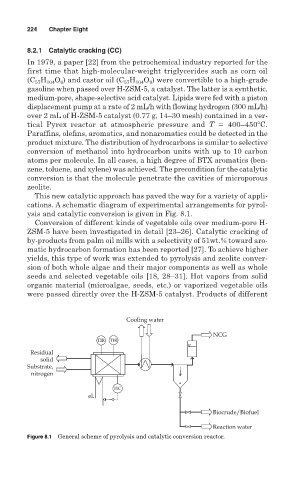

This new catalytic approach has paved the way for a variety of appli-

cations. A schematic diagram of experimental arrangements for pyrol-

ysis and catalytic conversion is given in Fig. 8.1.

Conversion of different kinds of vegetable oils over medium-pore H-

ZSM-5 have been investigated in detail [23–26]. Catalytic cracking of

by-products from palm oil mills with a selectivity of 51wt.% toward aro-

matic hydrocarbon formation has been reported [27]. To achieve higher

yields, this type of work was extended to pyrolysis and zeolite conver-

sion of both whole algae and their major components as well as whole

seeds and selected vegetable oils [18, 28–31]. Hot vapors from solid

organic material (microalgae, seeds, etc.) or vaporized vegetable oils

were passed directly over the H-ZSM-5 catalyst. Products of different

Cooling water

NCG

TIR TIR

Residual

solid

Substrate,

nitrogen

TIC

el.

Biocrude/Biofuel

Reaction water

Figure 8.1 General scheme of pyrolysis and catalytic conversion reactor.