Page 284 - Biofuels Refining and Performance

P. 284

Fuel Cells 263

design by improvement in the electrode structures, better electrocata-

lysts, more conductive electrolytes, thinner cell components, and so forth.

It is possible to improve the cell performance by modifying the operat-

ing conditions such as higher gas pressure, higher temperature, and a

change in gas composition to lower the gas impurity concentration [3].

9.3.2 Direct methanol fuel cells (DMFCs)

Direct methanol fuel cells are similar to the PEMFC as they also use a

polymer membrane as the electrolyte. However, it produces power by

direct conversion of liquid methanol to hydrogen ions on the anode side

of the fuel cell. In the DMFC, the anode catalyst draws hydrogen directly

from the liquid methanol, thus eliminating the need for a fuel reformer.

All the DMFC components (anode, cathode, membrane, and catalysts)

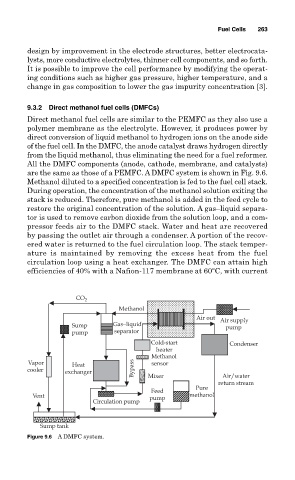

are the same as those of a PEMFC. A DMFC system is shown in Fig. 9.6.

Methanol diluted to a specified concentration is fed to the fuel cell stack.

During operation, the concentration of the methanol solution exiting the

stack is reduced. Therefore, pure methanol is added in the feed cycle to

restore the original concentration of the solution. A gas–liquid separa-

tor is used to remove carbon dioxide from the solution loop, and a com-

pressor feeds air to the DMFC stack. Water and heat are recovered

by passing the outlet air through a condenser. A portion of the recov-

ered water is returned to the fuel circulation loop. The stack temper-

ature is maintained by removing the excess heat from the fuel

circulation loop using a heat exchanger. The DMFC can attain high

efficiencies of 40% with a Nafion-117 membrane at 60 C, with current

CO 2

Methanol

Air out Air supply

Sump Gas–liquid pump

pump separator

Cold-start Condenser

heater

Methanol

Vapor Heat sensor

cooler exchanger Bypass Mixer Air/water

return stream

Pure

Feed

Vent pump methanol

Circulation pump

Sump tank

Figure 9.6 A DMFC system.