Page 383 - Biomedical Engineering and Design Handbook Volume 1, Fundamentals

P. 383

360 BIOMATERIALS

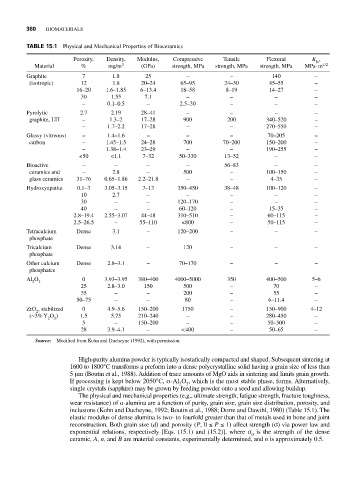

TABLE 15.1 Physical and Mechanical Properties of Bioceramics

Porosity, Density, Modulus, Compressive Tensile Flexural K ,

Ic

.

Material % mg/m 3 (GPa) strength, MPa strength, MPa strength, MPa MPa m 1/2

Graphite 7 1.8 25 – – 140 –

(isotropic) 12 1.8 20–24 65–95 24–30 45–55 –

16–20 1.6–1.85 6–13.4 18–58 8–19 14–27 –

30 1.55 7.1 – – – –

– 0.1–0.5 – 2.5–30 – – –

Pyrolytic 2.7 2.19 28–41 – – – –

graphite, LTI – 1.3–2 17–28 900 200 340–520 –

– 1.7–2.2 17–28 – – 270–550 –

Glassy (vitreous) – 1.4–1.6 – – – 70–205 –

carbon – 1.45–1.5 24–28 700 70–200 150–200 –

– 1.38–1.4 23–29 – – 190–255 –

≤50 <1.1 7–32 50–330 13–52 – –

Bioactive – – – – 56–83 – –

ceramics and – 2.8 – 500 – 100–150 –

glass ceramics 31–76 0.65–1.86 2.2–21.8 – – 4–35 –

Hydroxyapatite 0.1–3 3.05–3.15 7–13 350–450 38–48 100–120 –

10 2.7 – – – – –

30 – – 120–170 – – –

40 – – 60–120 – 15–35 –

2.8–19.4 2.55–3.07 44–48 310–510 – 60–115 –

2.5–26.5 – 55–110 ≤800 – 50–115 –

Tetracalcium Dense 3.1 – 120–200 – – –

phosphate

Tricalcium Dense 3.14 – 120 – – –

phosphate

Other calcium Dense 2.8–3.1 – 70–170 – – –

phosphates

Al O 0 3.93–3.95 380–400 4000–5000 350 400–500 5–6

2 3

25 2.8–3.0 150 500 – 70 –

35 – – 200 – 55 –

50–75 – – 80 – 6–11.4 –

ZrO , stabilized 0 4.9–5.6 150–200 1750 – 150–900 4–12

2

(~3% Y O ) 1.5 5.75 210–240 – – 280–450 –

2 3

5 – 150–200 – – 50–500 –

28 3.9–4.1 – < 400 – 50–65 –

Source: Modified from Kohn and Ducheyne (1992), with permission.

High-purity alumina powder is typically isostatically compacted and shaped. Subsequent sintering at

1600 to 1800°C transforms a preform into a dense polycrystalline solid having a grain size of less than

5 μm (Boutin et al., 1988). Addition of trace amounts of MgO aids in sintering and limits grain growth.

If processing is kept below 2050°C, α-Al O , which is the most stable phase, forms. Alternatively,

2 3

single crystals (sapphire) may be grown by feeding powder onto a seed and allowing buildup.

The physical and mechanical properties (e.g., ultimate strength, fatigue strength, fracture toughness,

wear resistance) of α-alumina are a function of purity, grain size, grain size distribution, porosity, and

inclusions (Kohn and Ducheyne, 1992; Boutin et al., 1988; Dorre and Dawihl, 1980) (Table 15.1). The

elastic modulus of dense alumina is two- to fourfold greater than that of metals used in bone and joint

reconstruction. Both grain size (d) and porosity (P, 0 ≤ P ≤ 1) affect strength (σ) via power law and

exponential relations, respectively [Eqs. (15.1) and (15.2)], where σ is the strength of the dense

0

ceramic, A, n, and B are material constants, experimentally determined, and n is approximately 0.5.