Page 231 - Biomedical Engineering and Design Handbook Volume 2, Applications

P. 231

210 MEDICAL DEVICE DESIGN

Production

packages

Bioburden

nominal sealing

parameters

Distribution

STERILIZATION Product

simulation

(w/validated process) sterility test

ASTM D 4169

Package integrity

Seal strength tests Seal strength tests

tests (Leak)

Pkgs meet

NO spec.

YES

PQ Completed

DOCUMENT

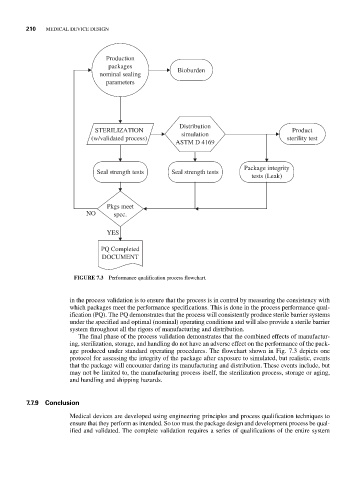

FIGURE 7.3 Performance qualification process flowchart.

in the process validation is to ensure that the process is in control by measuring the consistency with

which packages meet the performance specifications. This is done in the process performance qual-

ification (PQ). The PQ demonstrates that the process will consistently produce sterile barrier systems

under the specified and optimal (nominal) operating conditions and will also provide a sterile barrier

system throughout all the rigors of manufacturing and distribution.

The final phase of the process validation demonstrates that the combined effects of manufactur-

ing, sterilization, storage, and handling do not have an adverse effect on the performance of the pack-

age produced under standard operating procedures. The flowchart shown in Fig. 7.3 depicts one

protocol for assessing the integrity of the package after exposure to simulated, but realistic, events

that the package will encounter during its manufacturing and distribution. These events include, but

may not be limited to, the manufacturing process itself, the sterilization process, storage or aging,

and handling and shipping hazards.

7.7.9 Conclusion

Medical devices are developed using engineering principles and process qualification techniques to

ensure that they perform as intended. So too must the package design and development process be qual-

ified and validated. The complete validation requires a series of qualifications of the entire system