Page 233 - Biomedical Engineering and Design Handbook Volume 2, Applications

P. 233

212 MEDICAL DEVICE DESIGN

Compliance to the MDD’s “Essential Requirements” is met by using harmonized standards.

These standards may be European Norm (EN) or International Standards Organization (ISO) stan-

dards that meet the essential requirements of the directive. For the development of medical device

package systems, ISO 11607 has been developed and is used to meet essential packaging require-

ments of the directive. Specifically, for meeting the directive requirement as stated above, the revised

ISO 11607 provision states (f): “The following properties shall be evaluated: any shelf-life limita-

tions for presterilization and poststerilization storage.” Further, under Sec. 6.2.3 (i), “the design and

development of the package system shall consider . . . expiry date limitations of the product.” And

finally in Sec. 6.4, “Stability Testing,” “the stability testing shall demonstrate that the sterile barrier

system maintains integrity over time.”

The net result is that manufacturers must supply documented evidence to support product-

expiration claims. This is accomplished by monitoring measurable characteristics before, during, and

after the test to determine the effects of time on package performance.

Expiration claims could be documented by real-time shelf-life testing; however, the timelines for

product development would be adversely affected. The developers of the ISO 11607 standard recognized

this hindrance and therefore have allowed that “. . . stability testing using accelerated aging protocols

shall be regarded as sufficient evidence for claimed expiry dates until data from real-time aging studies

are available.” This provision is beneficial; however, no guidance is provided as to what conditions of

adverse severity are permissible or technically reliable. It therefore has become crucial that guidance and

standards be provided to help manufacturers establish product shelf-life and expiration claims.

7.8.1 10-Degree Rule

There are no published standard test methods for performing an accelerated aging study. However,

guidance on accelerated aging of packages is available from ASTM in the F1980, “Standard Guide

for Accelerated Aging of Sterile Medical Device Packages.” The ASTM guide was, in part, based on the

landmark technical paper by Robert Reich, which introduced the Von’t Hoff theory as an appropriate

rationale for the accelerated aging of packaging. This theory, based on the Arrhenius rate kinetics theory

of materials, states simply “a rise in temperature of 10°C will double the rate of a chemical reaction.”

The rule is commonly expressed as a Q value. So, for example, a doubling of the chemical reaction

10

rate makes the Q value 2.0. The aging factor (AF) is derived from the following equation:

10

AF = Q (T − T )/10

L

H

10

where Q = rate of chemical reaction (usually 2.0)

10

T = high temperature (test temperature)

H

T = low temperature (ambient)

L

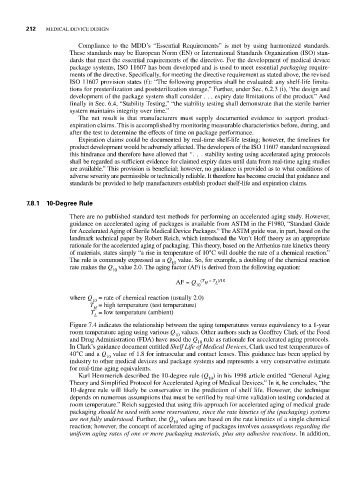

Figure 7.4 indicates the relationship between the aging temperatures versus equivalency to a 1-year

room temperature aging using various Q values. Other authors such as Geoffrey Clark of the Food

10

and Drug Administration (FDA) have used the Q rule as rationale for accelerated aging protocols.

10

In Clark’s guidance document entitled Shelf Life of Medical Devices, Clark used test temperatures of

40°C and a Q value of 1.8 for intraocular and contact lenses. This guidance has been applied by

10

industry to other medical devices and package systems and represents a very conservative estimate

for real-time aging equivalents.

Karl Hemmerich described the 10-degree rule (Q ) in his 1998 article entitled “General Aging

10

Theory and Simplified Protocol for Accelerated Aging of Medical Devices.” In it, he concludes, “the

10-degree rule will likely be conservative in the prediction of shelf life. However, the technique

depends on numerous assumptions that must be verified by real-time validation testing conducted at

room temperature.” Reich suggested that using this approach for accelerated aging of medical grade

packaging should be used with some reservations, since the rate kinetics of the (packaging) systems

are not fully understood. Further, the Q values are based on the rate kinetics of a single chemical

10

reaction; however, the concept of accelerated aging of packages involves assumptions regarding the

uniform aging rates of one or more packaging materials, plus any adhesive reactions. In addition,