Page 239 - Biomedical Engineering and Design Handbook Volume 2, Applications

P. 239

218 MEDICAL DEVICE DESIGN

Single sterile barrier

Systems Conceptual pkg. validation

for

(Produced at worst-case

sterile barrier system

process limits)

Sterile barrier

Baseline/ systems

control

Without product

Seal strength test

Sterilization

EtO Sterile barrier

systems

Seal integrity test

with product

Sterile barrier

systems

Without product

Seal strength test

Seal strength test 3 Year AA Environmental

ASTM F1980 extremes

Accel. Aged

55C/10% Seal integrity test

Seal integrity test 114 days

Seal strength test

Distribution

simulation

Seal integrity test

Final test report

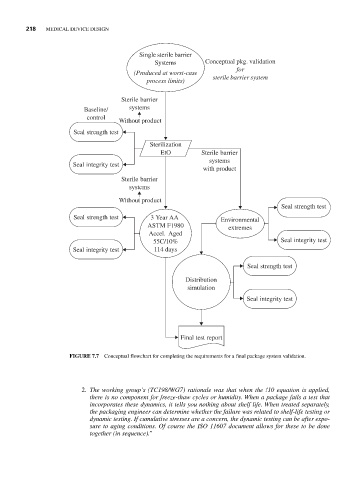

FIGURE 7.7 Conceptual flowchart for completing the requirements for a final package system validation.

2. The working group’s (TC198/WG7) rationale was that when the !10 equation is applied,

there is no component for freeze-thaw cycles or humidity. When a package fails a test that

incorporates these dynamics, it tells you nothing about shelf life. When treated separately,

the packaging engineer can determine whether the failure was related to shelf-life testing or

dynamic testing. If cumulative stresses are a concern, the dynamic testing can be after expo-

sure to aging conditions. Of course the ISO 11607 document allows for these to be done

together (in sequence).”