Page 158 - Boiler_Operators_Handbook,_Second_Edition

P. 158

Special Systems 143

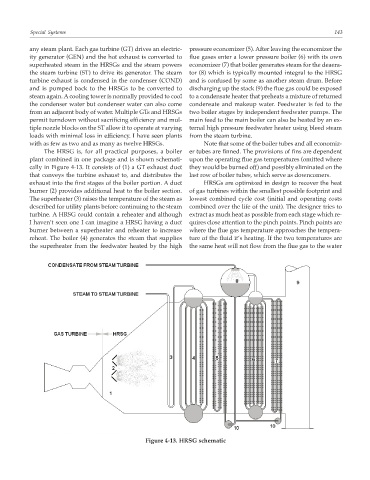

any steam plant. Each gas turbine (GT) drives an electric- pressure economizer (5). After leaving the economizer the

ity generator (GEN) and the hot exhaust is converted to flue gases enter a lower pressure boiler (6) with its own

superheated steam in the HRSGs and the steam powers economizer (7) that boiler generates steam for the deaera-

the steam turbine (ST) to drive its generator. The steam tor (8) which is typically mounted integral to the HRSG

turbine exhaust is condensed in the condenser (COND) and is confused by some as another steam drum. Before

and is pumped back to the HRSGs to be converted to discharging up the stack (9) the flue gas could be exposed

steam again. A cooling tower is normally provided to cool to a condensate heater that preheats a mixture of returned

the condenser water but condenser water can also come condensate and makeup water. Feedwater is fed to the

from an adjacent body of water. Multiple GTs and HRSGs two boiler stages by independent feedwater pumps. The

permit turndown without sacrificing efficiency and mul- main feed to the main boiler can also be heated by an ex-

tiple nozzle blocks on the ST allow it to operate at varying ternal high pressure feedwater heater using bleed steam

loads with minimal loss in efficiency. I have seen plants from the steam turbine.

with as few as two and as many as twelve HRSGs. Note that some of the boiler tubes and all economiz-

The HRSG is, for all practical purposes, a boiler er tubes are finned. The provisions of fins are dependent

plant combined in one package and is shown schemati- upon the operating flue gas temperatures (omitted where

cally in Figure 4-13. It consists of (1) a GT exhaust duct they would be burned off) and possibly eliminated on the

that conveys the turbine exhaust to, and distributes the last row of boiler tubes, which serve as downcomers.

exhaust into the first stages of the boiler portion. A duct HRSGs are optimized in design to recover the heat

burner (2) provides additional heat to the boiler section. of gas turbines within the smallest possible footprint and

The superheater (3) raises the temperature of the steam as lowest combined cycle cost (initial and operating costs

described for utility plants before continuing to the steam combined over the life of the unit). The designer tries to

turbine. A HRSG could contain a reheater and although extract as much heat as possible from each stage which re-

I haven’t seen one I can imagine a HRSG having a duct quires close attention to the pinch points. Pinch points are

burner between a superheater and reheater to increase where the flue gas temperature approaches the tempera-

reheat. The boiler (4) generates the steam that supplies ture of the fluid it’s heating. If the two temperatures are

the superheater from the feedwater heated by the high the same heat will not flow from the flue gas to the water

Figure 4-13. HRSG schematic