Page 156 - Boiler_Operators_Handbook,_Second_Edition

P. 156

Special Systems 141

turning, however, lubrication has to be established and

proven.

Maintenance of lubricating oil temperatures dur-

ing a GTs operation is very important because the oil

can be too cool as well as too hot. Other temperatures

that should be monitored closely are compressor exhaust

temperature, burner exhaust temperature, and turbine

exhaust temperature. The first two must be within limits

for continued operation and the last as low as possible for

maximum turbine efficiency.

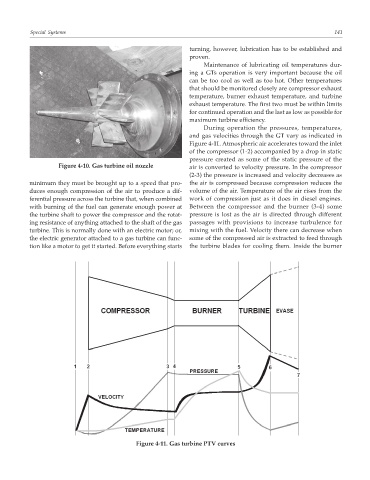

During operation the pressures, temperatures,

and gas velocities through the GT vary as indicated in

Figure 4-11. Atmospheric air accelerates toward the inlet

of the compressor (1-2) accompanied by a drop in static

pressure created as some of the static pressure of the

Figure 4-10. Gas turbine oil nozzle air is converted to velocity pressure. In the compressor

(2-3) the pressure is increased and velocity decreases as

minimum they must be brought up to a speed that pro- the air is compressed because compression reduces the

duces enough compression of the air to produce a dif- volume of the air. Temperature of the air rises from the

ferential pressure across the turbine that, when combined work of compression just as it does in diesel engines.

with burning of the fuel can generate enough power at Between the compressor and the burner (3-4) some

the turbine shaft to power the compressor and the rotat- pressure is lost as the air is directed through different

ing resistance of anything attached to the shaft of the gas passages with provisions to increase turbulence for

turbine. This is normally done with an electric motor; or, mixing with the fuel. Velocity there can decrease when

the electric generator attached to a gas turbine can func- some of the compressed air is extracted to feed through

tion like a motor to get it started. Before everything starts the turbine blades for cooling them. Inside the burner

Figure 4-11. Gas turbine PTV curves