Page 193 - Boiler_Operators_Handbook,_Second_Edition

P. 193

178 Boiler Operator’s Handbook

The fill is designed to convert the falling water to a film air velocities in the tower that are higher than design.

along the surface of the fill and thin sheets or droplets of Sometimes it only occurs at high loads but it can be a

water between parts of the fill. The air is drawn through problem at lower loads if the fill is distorted, damaged,

the fill to contact the air over that extended surface to covered with organic growth or otherwise altered to re-

achieve the heat transfer and sweep vaporized water out duce or block air flow in some parts of the tower so the

of the tower. The fill can consist of redwood slats in sev- velocities have to be higher in other parts to compensate

eral alternating layers (Figure 5-38) but so many of them for it. Towers can contain baffles to redirect water splash-

burned up when idled during the winter that it’s an un- ing off the fill back into the tower and they can be bent

common material in towers today, used primarily where or otherwise altered by high winds, falling tree limbs,

the tower is always in service. There are many variations and accidents to increase liquid water loss. Drift is sim-

and designs of plastic fill used today. ply a waste of water and should be addressed when it

Part of the plume can be drift. Drift identifies drop- is detected. Consistent pools of water on adjacent roofs

lets of water that are swept off the fill by the air and (evident in Figure 5-37) are indications of drift.

leave the tower without being vaporized. Those drop- Cooling towers in electric power plants and large

lets are usually much larger than the fog and drop out industrial plants can operate without a fan forcing the

on adjacent structures. Excessive drift is an indication of flow of the air. You’re probably familiar with photo-

graphs of nuclear power plants and the

tall hyperbolic cooling towers (Figure

5-39) which use the differential pres-

sure produced by the difference in den-

sity of the atmospheric air and the air

heated in the towers and containing

a larger volume of lighter steam. The

plume that we associate with cooling

towers is actually droplets of water that

condense as the exhaust of the cooling

tower is cooled by the slightly cooler

atmospheric air. A better name for that

plume would be fog.

In an electric power plant colder

condenser water, cooled by the cool-

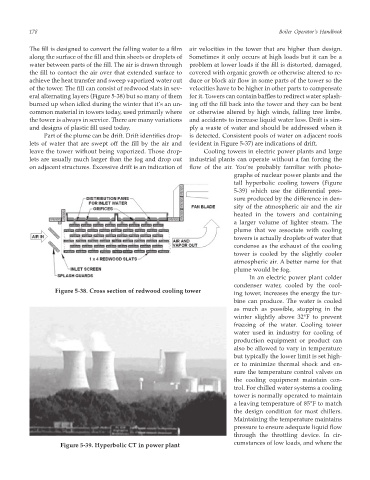

Figure 5-38. Cross section of redwood cooling tower

ing tower, increases the energy the tur-

bine can produce. The water is cooled

as much as possible, stopping in the

winter slightly above 32°F to prevent

freezing of the water. Cooling tower

water used in industry for cooling of

production equipment or product can

also be allowed to vary in temperature

but typically the lower limit is set high-

er to minimize thermal shock and en-

sure the temperature control valves on

the cooling equipment maintain con-

trol. For chilled water systems a cooling

tower is normally operated to maintain

a leaving temperature of 85°F to match

the design condition for most chillers.

Maintaining the temperature maintains

pressure to ensure adequate liquid flow

through the throttling device. In cir-

cumstances of low loads, and where the

Figure 5-39. Hyperbolic CT in power plant