Page 191 - Boiler_Operators_Handbook,_Second_Edition

P. 191

176 Boiler Operator’s Handbook

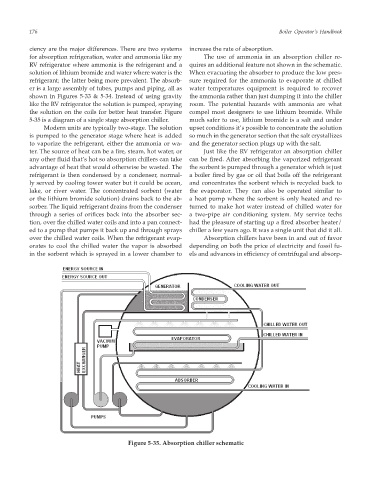

ciency are the major differences. There are two systems increase the rate of absorption.

for absorption refrigeration, water and ammonia like my The use of ammonia in an absorption chiller re-

RV refrigerator where ammonia is the refrigerant and a quires an additional feature not shown in the schematic.

solution of lithium bromide and water where water is the When evacuating the absorber to produce the low pres-

refrigerant; the latter being more prevalent. The absorb- sure required for the ammonia to evaporate at chilled

er is a large assembly of tubes, pumps and piping, all as water temperatures equipment is required to recover

shown in Figures 5-33 & 5-34. Instead of using gravity the ammonia rather than just dumping it into the chiller

like the RV refrigerator the solution is pumped, spraying room. The potential hazards with ammonia are what

the solution on the coils for better heat transfer. Figure compel most designers to use lithium bromide. While

5-35 is a diagram of a single stage absorption chiller. much safer to use, lithium bromide is a salt and under

Modern units are typically two-stage. The solution upset conditions it’s possible to concentrate the solution

is pumped to the generator stage where heat is added so much in the generator section that the salt crystallizes

to vaporize the refrigerant, either the ammonia or wa- and the generator section plugs up with the salt.

ter. The source of heat can be a fire, steam, hot water, or Just like the RV refrigerator an absorption chiller

any other fluid that’s hot so absorption chillers can take can be fired. After absorbing the vaporized refrigerant

advantage of heat that would otherwise be wasted. The the sorbent is pumped through a generator which is just

refrigerant is then condensed by a condenser, normal- a boiler fired by gas or oil that boils off the refrigerant

ly served by cooling tower water but it could be ocean, and concentrates the sorbent which is recycled back to

lake, or river water. The concentrated sorbent (water the evaporator. They can also be operated similar to

or the lithium bromide solution) drains back to the ab- a heat pump where the sorbent is only heated and re-

sorber. The liquid refrigerant drains from the condenser turned to make hot water instead of chilled water for

through a series of orifices back into the absorber sec- a two-pipe air conditioning system. My service techs

tion, over the chilled water coils and into a pan connect- had the pleasure of starting up a fired absorber heater/

ed to a pump that pumps it back up and through sprays chiller a few years ago. It was a single unit that did it all.

over the chilled water coils. When the refrigerant evap- Absorption chillers have been in and out of favor

orates to cool the chilled water the vapor is absorbed depending on both the price of electricity and fossil fu-

in the sorbent which is sprayed in a lower chamber to els and advances in efficiency of centrifugal and absorp-

Figure 5-35. Absorption chiller schematic