Page 294 - Boiler_Operators_Handbook,_Second_Edition

P. 294

Plants and Equipment 279

a setting or casing, insulation and refractory. The typical

form was a box. and could consist of a mixture of ma-

terials. Boilers were constructed with bottom support,

top and intermediate support. Top supported boilers re-

quire inverted thinking because they grow down as the

boiler heats up. Intermediate supported units grow both

ways. Top supported boilers required an external struc-

tural steel frame to hang from; sometimes they are made

part of the building and other times they’re independent

of the building.

Yes, boilers grow. There’s a list of materials and

the amount their length changes in the appendix. Since

a boiler is made mostly of steel it will grow around 0.6%

for each one degree change in temperature. The steel

in a boiler will always be very close to the temperature

of the steam or water (saturation condition for a steam

boiler, average temperature for hot water). So, if the Figure 10-3. Cast iron boiler, integral furnace

boiler is supported at the top, basically hanging from the

structural steel, it will grow down. If it’s supported at

the bottom it will grow up. We don’t attach the boiler to

the building structure, the tendency of boilers to grow as

they are heated prevents it. There are times when you’ll

find some platforms supported off the boiler steel; be

aware that they will move!

Today there are three basic types of boiler con-

struction, cast iron, firetube and watertube. Cast iron

forms produce spaces for water, the fire, and products

of combustion. A firetube boiler contains the fire and

products of combustion inside the tubes and the water

and steam is outside the tube. A watertube boiler has

the fluids on the other side, tubes surround the water

and the fire and flue gas is on the outside of the tubes.

There are also tubeless boilers (which I would classify

as firetube) that, like the whistling teapot on your stove,

are small and inefficient but are so cheap to build they

are more than adequate for some small operations.

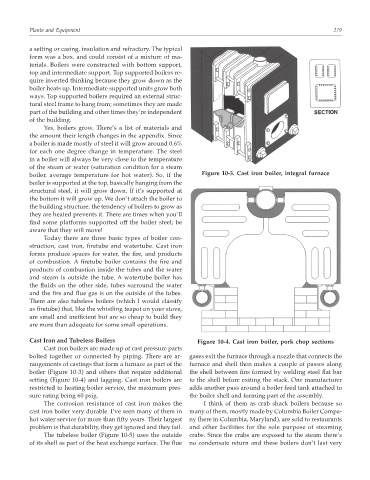

Cast Iron and Tubeless Boilers Figure 10-4. Cast iron boiler, pork chop sections

Cast iron boilers are made up of cast pressure parts

bolted together or connected by piping. There are ar- gases exit the furnace through a nozzle that connects the

rangements of castings that form a furnace as part of the furnace and shell then makes a couple of passes along

boiler (Figure 10-3) and others that require additional the shell between fins formed by welding steel flat bar

setting (Figure 10-4) and lagging. Cast iron boilers are to the shell before exiting the stack. One manufacturer

restricted to heating boiler service, the maximum pres- adds another pass around a boiler feed tank attached to

sure rating being 60 psig. the boiler shell and forming part of the assembly.

The corrosion resistance of cast iron makes the I think of them as crab shack boilers because so

cast iron boiler very durable. I’ve seen many of them in many of them, mostly made by Columbia Boiler Compa-

hot water service for more than fifty years. Their largest ny (here in Columbia, Maryland), are sold to restaurants

problem is that durability, they get ignored and they fail. and other facilities for the sole purpose of steaming

The tubeless boiler (Figure 10-5) uses the outside crabs. Since the crabs are exposed to the steam there’s

of its shell as part of the heat exchange surface. The flue no condensate return and these boilers don’t last very