Page 298 - Boiler_Operators_Handbook,_Second_Edition

P. 298

Plants and Equipment 283

viding two passes, the flue gases are turned and return

down a portion of the tubes on their way to the stack.

Note that a pass consists of a path for flue gas to

travel from one extreme end of the flue gas containing

parts of the boiler to another. Neither of these designs

required a baffle to direct the flow of flue gas. Scotch

marine designs can have two, three, or four passes. A

two pass scotch marine boiler requires no baffles other

than means to separate the burner from the returning

flue gas. Three pass scotch marine construction requires

one baffle in the rear of the boiler to separate the first

and second pass turning box from the third pass outlet

while four pass boilers require a baffle there plus one at

the front to separate the second and third pass turning

box from the fourth pass outlet (Figure 10-13).

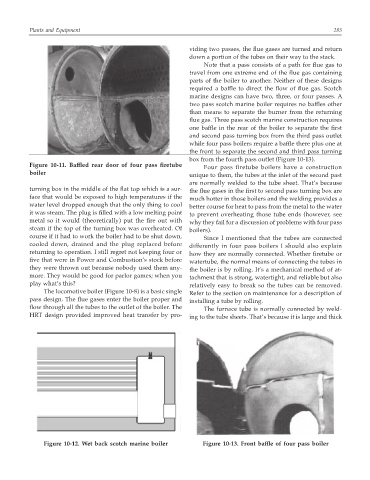

Figure 10-11. Baffled rear door of four pass firetube Four pass firetube boilers have a construction

boiler unique to them, the tubes at the inlet of the second past

are normally welded to the tube sheet. That’s because

turning box in the middle of the flat top which is a sur- the flue gases in the first to second pass turning box are

face that would be exposed to high temperatures if the much hotter in those boilers and the welding provides a

water level dropped enough that the only thing to cool better course for heat to pass from the metal to the water

it was steam. The plug is filled with a low melting point to prevent overheating those tube ends (however, see

metal so it would (theoretically) put the fire out with why they fail for a discussion of problems with four pass

steam if the top of the turning box was overheated. Of boilers).

course if it had to work the boiler had to be shut down, Since I mentioned that the tubes are connected

cooled down, drained and the plug replaced before differently in four pass boilers I should also explain

returning to operation. I still regret not keeping four or how they are normally connected. Whether firetube or

five that were in Power and Combustion’s stock before watertube, the normal means of connecting the tubes in

they were thrown out because nobody used them any- the boiler is by rolling. It’s a mechanical method of at-

more. They would be good for parlor games; when you tachment that is strong, watertight, and reliable but also

play what’s this? relatively easy to break so the tubes can be removed.

The locomotive boiler (Figure 10-8) is a basic single Refer to the section on maintenance for a description of

pass design. The flue gases enter the boiler proper and installing a tube by rolling.

flow through all the tubes to the outlet of the boiler. The The furnace tube is normally connected by weld-

HRT design provided improved heat transfer by pro- ing to the tube sheets. That’s because it is large and thick

Figure 10-12. Wet back scotch marine boiler Figure 10-13. Front baffle of four pass boiler