Page 300 - Boiler_Operators_Handbook,_Second_Edition

P. 300

Plants and Equipment 285

and provide a place for steam and water to separate. the boiler room cool and limiting the cost of refractory

I’ve never come across a distinctive definition that was.

differentiates drums and headers but I know drums are Another problem was refractory walls were get-

big and headers are small and I differentiate them by ting so high they couldn’t be self supporting and ex-

whether or not I can get inside one with the exception pensive structural steel was required to hold them up.

of the steam drum which, to me, is always the pressure To solve many of those problems boiler manufacturers

vessel part where the steam and water are separated. started making water walls which are rows of tubes that

That rule doesn’t always work when it comes to what help protect the refractory or actually replace it. The

we call a mud drum which is the lowest drum in a boiler waterwalls on large utility boilers actually occupy more

and has connecting piping for blowoff so the mud can be space than the boiler itself. Most of them are tangent

removed from the boiler. I can’t say it’s the lowest point tube walls (described later) and constructed in “panels”

because there are boilers where the mud drum is several that are subsequently welded together to form water-

feet higher than the lowest header. Those low headers walls, some over two hundred feet tall.

have to be blown down because mud will collect in them Waterwalls consist of tubes that may be bent to

but they require special attention to prevent problems connect to a steam or mud drum or connect to a header

with circulation during the process. Anyway, drums that is connected to one of the drums with more tubes.

close off the ends of tubes and it’s the tube and drum ar- Despite the two nameplate labeling (which was aban-

rangement that further defines a watertube boiler. There doned shortly after it was started) the waterwalls and

were a few firetube / watertube combinations created boiler are all parts of the same pressure vessel.

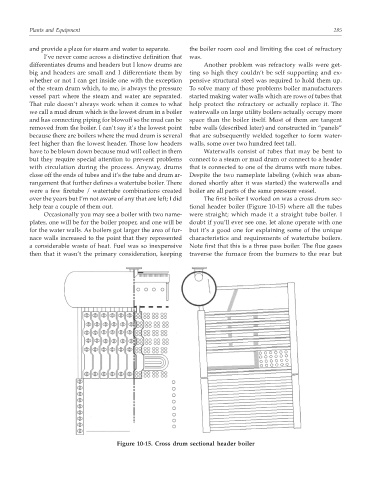

over the years but I’m not aware of any that are left; I did The first boiler I worked on was a cross drum sec-

help tear a couple of them out. tional header boiler (Figure 10-15) where all the tubes

Occasionally you may see a boiler with two name- were straight; which made it a straight tube boiler. I

plates, one will be for the boiler proper, and one will be doubt if you’ll ever see one, let alone operate with one

for the water walls. As boilers got larger the area of fur- but it’s a good one for explaining some of the unique

nace walls increased to the point that they represented characteristics and requirements of watertube boilers.

a considerable waste of heat. Fuel was so inexpensive Note first that this is a three pass boiler. The flue gases

then that it wasn’t the primary consideration, keeping traverse the furnace from the burners to the rear but

Figure 10-15. Cross drum sectional header boiler