Page 304 - Boiler_Operators_Handbook,_Second_Edition

P. 304

Plants and Equipment 289

spread over the front wall to help protect the refractory. The predominant design is the D type (Figure 10-

The rear wall, on the other hand, is usually fit- 21) which has only one drawback and that’s the problem

ted with bent tubes spread out to cover it. The wall is with transporting and supporting something with most

typically much lighter in construction than the front of the weight on one side. The D tubes extend out of the

wall, an allowance partially provided by the tubes and drum to form the roof of the furnace, drop to form the

distance from the heat of the flame. Frequently the rear furnace side wall, and return under the furnace to the

wall is called the target wall because the flame is shoot- mud drum. It has one convection bank of tubes centered

ing straight at it and the tubes against the rear wall are between the drums to limit sootblower requirements.

called target tubes. The tubes form a framework of steel This construction makes it possible for the flue gas to

that helps to hold the rear wall in place, especially dur- leave the boiler via the front or side. A more detailed

ing shipment of the boiler and that’s a major consider- diagram (Figure 10-22) will help you identify some of

ation in the wall thickness. the standard features of this construction.

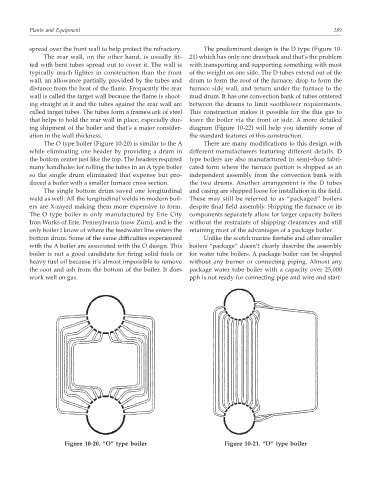

The O type boiler (Figure 10-20) is similar to the A There are many modifications to this design with

while eliminating one header by providing a drum in different manufacturers featuring different details. D

the bottom center just like the top. The headers required type boilers are also manufactured in semi-shop fabri-

many handholes for rolling the tubes in an A type boiler cated form where the furnace portion is shipped as an

so the single drum eliminated that expense but pro- independent assembly from the convection bank with

duced a boiler with a smaller furnace cross section. the two drums. Another arrangement is the D tubes

The single bottom drum saved one longitudinal and casing are shipped loose for installation in the field.

weld as well. All the longitudinal welds in modern boil- These may still be referred to as “packaged” boilers

ers are X-rayed making them more expensive to form. despite final field assembly. Shipping the furnace or its

The O type boiler is only manufactured by Erie City components separately allow for larger capacity boilers

Iron Works of Erie, Pennsylvania (now Zurn), and is the without the restraints of shipping clearances and still

only boiler I know of where the feedwater line enters the retaining most of the advantages of a package boiler.

bottom drum. Some of the same difficulties experienced Unlike the scotch marine firetube and other smaller

with the A boiler are associated with the O design. This boilers “package” doesn’t clearly describe the assembly

boiler is not a good candidate for firing solid fuels or for water tube boilers. A package boiler can be shipped

heavy fuel oil because it’s almost impossible to remove without any burner or connecting piping. Almost any

the soot and ash from the bottom of the boiler. It does package water tube boiler with a capacity over 25,000

work well on gas. pph is not ready for connecting pipe and wire and start-

Figure 10-20. “O” type boiler Figure 10-21. “D” type boiler