Page 309 - Boiler_Operators_Handbook,_Second_Edition

P. 309

294 Boiler Operator’s Handbook

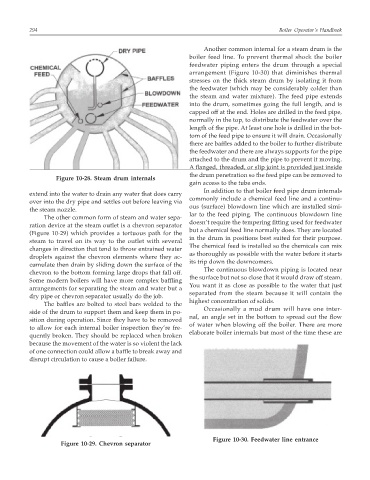

Another common internal for a steam drum is the

boiler feed line. To prevent thermal shock the boiler

feedwater piping enters the drum through a special

arrangement (Figure 10-30) that diminishes thermal

stresses on the thick steam drum by isolating it from

the feedwater (which may be considerably colder than

the steam and water mixture). The feed pipe extends

into the drum, sometimes going the full length, and is

capped off at the end. Holes are drilled in the feed pipe,

normally in the top, to distribute the feedwater over the

length of the pipe. At least one hole is drilled in the bot-

tom of the feed pipe to ensure it will drain. Occasionally

there are baffles added to the boiler to further distribute

the feedwater and there are always supports for the pipe

attached to the drum and the pipe to prevent it moving.

A flanged, threaded, or slip joint is provided just inside

the drum penetration so the feed pipe can be removed to

Figure 10-28. Steam drum internals

gain access to the tube ends.

In addition to that boiler feed pipe drum internals

extend into the water to drain any water that does carry

commonly include a chemical feed line and a continu-

over into the dry pipe and settles out before leaving via

ous (surface) blowdown line which are installed simi-

the steam nozzle.

lar to the feed piping. The continuous blowdown line

The other common form of steam and water sepa-

doesn’t require the tempering fitting used for feedwater

ration device at the steam outlet is a chevron separator

but a chemical feed line normally does. They are located

(Figure 10-29) which provides a tortuous path for the

in the drum in positions best suited for their purpose.

steam to travel on its way to the outlet with several

The chemical feed is installed so the chemicals can mix

changes in direction that tend to throw entrained water

as thoroughly as possible with the water before it starts

droplets against the chevron elements where they ac-

its trip down the downcomers.

cumulate then drain by sliding down the surface of the

The continuous blowdown piping is located near

chevron to the bottom forming large drops that fall off.

the surface but not so close that it would draw off steam.

Some modern boilers will have more complex baffling

You want it as close as possible to the water that just

arrangements for separating the steam and water but a

separated from the steam because it will contain the

dry pipe or chevron separator usually do the job.

highest concentration of solids.

The baffles are bolted to steel bars welded to the

Occasionally a mud drum will have one inter-

side of the drum to support them and keep them in po-

nal, an angle set in the bottom to spread out the flow

sition during operation. Since they have to be removed

of water when blowing off the boiler. There are more

to allow for each internal boiler inspection they’re fre-

elaborate boiler internals but most of the time these are

quently broken. They should be replaced when broken

because the movement of the water is so violent the lack

of one connection could allow a baffle to break away and

disrupt circulation to cause a boiler failure.

Figure 10-30. Feedwater line entrance

Figure 10-29. Chevron separator