Page 297 - Boiler_Operators_Handbook,_Second_Edition

P. 297

282 Boiler Operator’s Handbook

commonly used for service water heating (Figure 4-9)

and may find occasional use for hydronic heating and in

waste heat service.

A locomotive boiler (Figure 10-8) is a good exam-

ple of a firetube boiler modified to provide some water

cooling of the furnace. The increased cost of the boiler

to create a water jacket around the furnace was justified

for locomotive service because the steel and water were

considerably lighter than the refractory that would be

required while providing more heating surface to make

the locomotive more powerful. Staybolts are used to

hold the flat surfaces against the internal pressure and

their failure was one reason many of these boilers are no

longer around.

The techniques developed in the railroad industry

were translated to stationary boilers to create the fire-

box boiler (Figure 10-9). The firebox boiler was the first

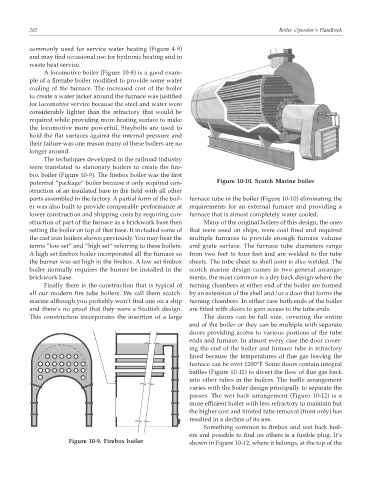

potential “package” boiler because it only required con- Figure 10-10. Scotch Marine boiler

struction of an insulated base in the field with all other

parts assembled in the factory. A partial form of the boil- furnace tube in the boiler (Figure 10-10) eliminating the

er was also built to provide comparable performance at requirements for an external furnace and providing a

lower construction and shipping costs by requiring con- furnace that is almost completely water cooled.

struction of part of the furnace as a brickwork base then Many of the original boilers of this design, the ones

setting the boiler on top of that base. It included some of that were used on ships, were coal fired and required

the cast iron boilers shown previously. You may hear the multiple furnaces to provide enough furnace volume

terms “low set” and “high set” referring to these boilers. and grate surface. The furnace tube diameters range

A high set firebox boiler incorporated all the furnace so from two feet to four feet and are welded to the tube

the burner was set high in the firebox. A low set firebox sheets. The tube sheet to shell joint is also welded. The

boiler normally requires the burner be installed in the scotch marine design comes in two general arrange-

brickwork base. ments, the most common is a dry back design where the

Finally there is the construction that is typical of turning chambers at either end of the boiler are formed

all our modern fire tube boilers. We call them scotch- by an extension of the shell and/or a door that forms the

marine although you probably won’t find one on a ship turning chambers. In either case both ends of the boiler

and there’s no proof that they were a Scottish design. are fitted with doors to gain access to the tube ends.

This construction incorporates the insertion of a large The doors can be full size, covering the entire

end of the boiler or they can be multiple with separate

doors providing access to various portions of the tube

ends and furnace. In almost every case the door cover-

ing the end of the boiler and furnace tube is refractory

lined because the temperatures of flue gas leaving the

furnace can be over 1200°F. Some doors contain integral

baffles (Figure 10-11) to divert the flow of flue gas back

into other tubes in the boilers. The baffle arrangement

varies with the boiler design principally to separate the

passes. The wet back arrangement (Figure 10-12) is a

more efficient boiler with less refractory to maintain but

the higher cost and limited tube removal (front only) has

resulted in a decline of its use.

Something common to firebox and wet back boil-

ers and possible to find on others is a fusible plug. It’s

Figure 10-9. Firebox boiler shown in Figure 10-12, where it belongs, at the top of the