Page 366 - Boiler_Operators_Handbook,_Second_Edition

P. 366

Plants and Equipment 351

They’re commonly used to produce a vacuum in a con- possible to compress a liquid a little but most compres-

denser. Another common use is to remove condensate sors will simply break if you try to compress a liquid

and rain water from underground vaults containing with them. That sounds like a simple and straightfor-

steam piping. An ejector with a float actuated steam ward statement but I know a few operators that have

shutoff valve is the least expensive means of automati- tried to compress water or lubricating oil with devastat-

cally clearing water from underground piping vaults ing results.

and they’re quite reliable. Compression is simply packing more pounds of a

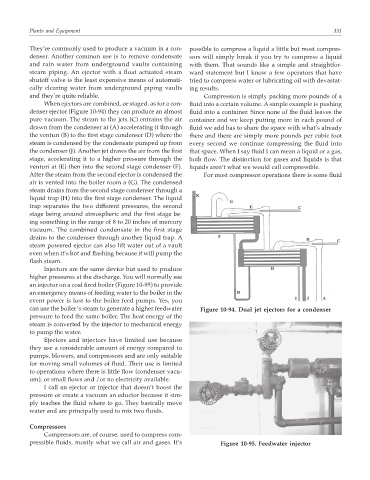

When ejectors are combined, or staged, as for a con- fluid into a certain volume. A simple example is pushing

denser ejector (Figure 10-94) they can produce an almost fluid into a container. Since none of the fluid leaves the

pure vacuum. The steam to the jets (C) entrains the air container and we keep putting more in each pound of

drawn from the condenser at (A) accelerating it through fluid we add has to share the space with what’s already

the venturi (B) to the first stage condenser (D) where the there and there are simply more pounds per cubic foot

steam is condensed by the condensate pumped up from every second we continue compressing the fluid into

the condenser (J). Another jet draws the air from the first that space. When I say fluid I can mean a liquid or a gas,

stage, accelerating it to a higher pressure through the both flow. The distinction for gases and liquids is that

venturi at (E) then into the second stage condenser (F). liquids aren’t what we would call compressible.

After the steam from the second ejector is condensed the For most compressor operations there is some fluid

air is vented into the boiler room a (G). The condensed

steam drains from the second stage condenser through a

liquid trap (H) into the first stage condenser. The liquid

trap separates the two different pressures, the second

stage being around atmospheric and the first stage be-

ing something in the range of 8 to 20 inches of mercury

vacuum. The combined condensate in the first stage

drains to the condenser through another liquid trap. A

steam powered ejector can also lift water out of a vault

even when it’s hot and flashing because it will pump the

flash steam.

Injectors are the same device but used to produce

higher pressures at the discharge. You will normally see

an injector on a coal fired boiler (Figure 10-95) to provide

an emergency means of feeding water to the boiler in the

event power is lost to the boiler feed pumps. Yes, you

can use the boiler’s steam to generate a higher feedwater Figure 10-94. Dual jet ejectors for a condenser

pressure to feed the same boiler. The heat energy of the

steam is converted by the injector to mechanical energy

to pump the water.

Ejectors and injectors have limited use because

they use a considerable amount of energy compared to

pumps, blowers, and compressors and are only suitable

for moving small volumes of fluid. Their use is limited

to operations where there is little flow (condenser vacu-

um), or small flows and /or no electricity available.

I call an ejector or injector that doesn’t boost the

pressure or create a vacuum an eductor because it sim-

ply teaches the fluid where to go. They basically move

water and are principally used to mix two fluids.

Compressors

Compressors are, of course, used to compress com-

pressible fluids, mostly what we call air and gases. It’s Figure 10-95. Feedwater injector